By Ian B. Cooper, University Center of Excellence for Photovoltaics Research and Education, Georgia Institute of Technology; Keith Tate, University Center of Excellence for Photovoltaics Research and Education, Georgia Institute of Technology; Moon Hee Kang, University Center of Excellence for Photovoltaics Research and Education, Georgia Institute of Technology; Alan F. Carroll, Research Fellow, DuPont Microcircuit Materials, Research Triangle Park; Kurt R. Mikeska, Senior Research Associate, DuPont Central Research & Development; Robert C. Reedy, Senior Engineer, National Renewable Energy Laboratory; Ajeet Rohatgi, Director, University Center of Excellence for Photovoltaics Research and Education, Georgia Institute of Technology

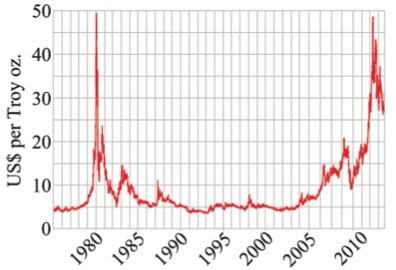

The market price of Ag has fluctuated considerably over the past ten years and has impacted the manufacturing cost of Si solar cells and the price of Si PV. Reducing Ag consumption can decrease this cost; however, such reduction may come at the expense of cell performance. In order to address the issue of Ag cost reduction while maintaining high cell efficiency, phosphorus emitter profiles are tailored via POCl3 diffusion to create solar cell emitters displaying low saturation current density (J0e), variable electrically active surface phosphorus concentration ([Psurface]), and variable sheet resistance with the aim of reducing Ag consumption. By optimizing emitter diffusion conditions, it is possible to reduce screen-printed Ag paste consumption by 33% with no loss in cell performance. Using a screen-printable Ag conductor paste designed to contact low [Psurface] emitters, the performance of cells with screen-printed Ag paste dry masses of 200, 120 and 80mg is compared. By using a tailored low-J0e 55Ω/sq emitter, it is possible to achieve a high open-circuit voltage (Voc) and short-circuit current (Jsc) to yield average cell efficiencies of 18.64% and 18.73% for 120mg and 80mg Ag paste dry mass, respectively. This is compared with efficiencies of 18.52% for cells using state-of-the-art technology (industrial high [Psurface] 65Ω/sq emitter with 120mg Ag paste dry mass). On the basis of a Ag market price of US$32/troy oz and an 85% by weight thick-film paste Ag metal content, a Ag front-side metallization cost of US¢2.11/W can be achieved by using 80mg Ag paste dry mass, which translates to a Ag cost saving of US$5.4M per year for a 500MW production line when compared with the Ag cost for state-of-the-art technology. Further cost analysis shows a 1.2% area-related balance of system (BOS) cost reduction and a US¢0.1/kWh reduction when comparing low-J0e 55Ω/sq modules and state-of-the-art modules. Calculations show that an additional 0.5% absolute efficiency for state-of-the-art modules is required, to compensate the efficiency gains and Ag cost reduction afforded by low-J0e 55Ω/sq modules.