By Hariharsudan Sivaramakrishnan Radhakrishnan, (Hari) pursued his Ph.D research at KU Leuven and imec, Belgium, on porous silicon-based gettering and epitaxial Si lift-off and solar cells.; Valérie Depauw, is a research engineer at imec, involved in several EU projects. She started playing with lif t-off techniques at the end of 2004, at the start of her Ph.D, and has not stopped since then. She has built expertise around making “holes” inside silicon, by tailoring porous silicon for kerfless wafering and exploring advanced nanostructures for light trapping in (ultra-) thin crystalline-silicon solar cells.; Kris Van Nieuwenhuysen, Kris Van Nieuwenhuysen obtained her degree in engineering in 2000. She then joined the Si solar cell group of imec, where she has been the main expert in Si epitaxial CVD processes for solar cell fabrication.; Ivan Gordon, obtained his Ph.D from the University of Leuven, Belgium in February 2002. He started to work at imec in June 2003, where he is currently leading the Silicon Photovoltaics group, working on c-Si wafer-based solar cells, thin-film silicon solar cells, and advanced module concepts for ultra-thin c-Si wafer-based cells.; Jef Poortmans, received his Ph.D from the KU Leuven, Belgium, in June 1993. Afterwards he joined the photovoltaics group and, in 2003, became the PV Department Director.

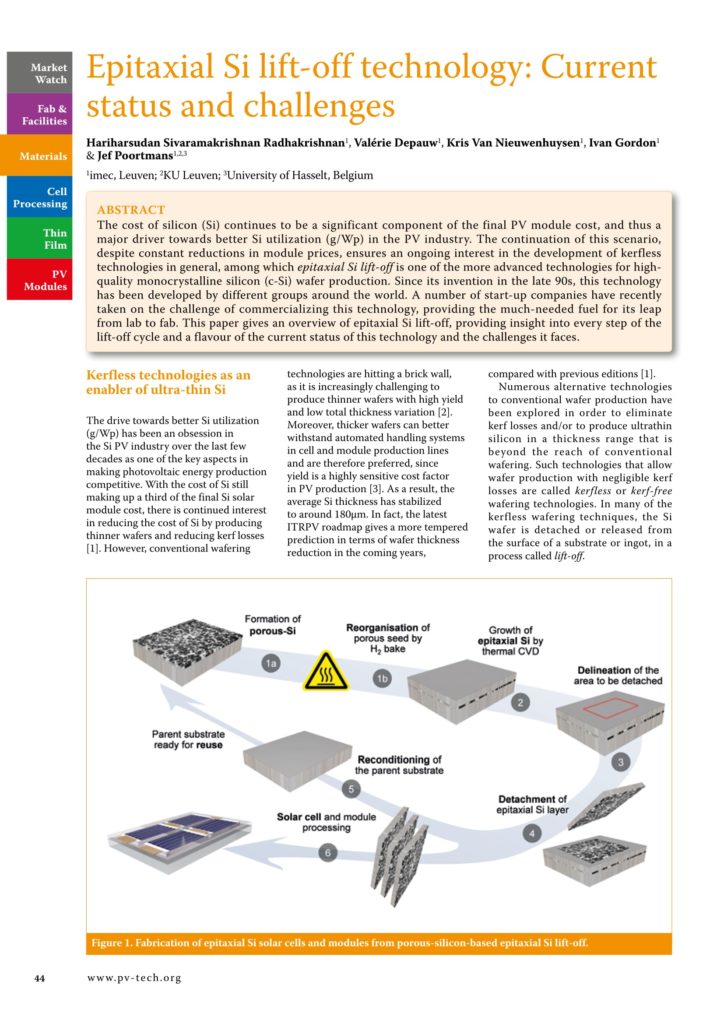

The drive towards better Si utilization (g/Wp) has been an obsession in the Si PV industry over the last few decades as one of the key aspects in making photovoltaic energy production competitive. With the cost of Si still making up a third of the final Si solar module cost, there is continued interest in reducing the cost of Si by producing thinner wafers and reducing kerf losses.