By Cameron Stark, Member of Technical Staff, Fraunhofer Center for Sustainable Energy Systems CSE; Claudio Ferrara, Head of the Weathering and Reliability Department, Fraunhofer ISE; Cordula Schmid, PV Technologies Team, Fraunhofer CSE; Sandor Stecklum, Test Engineer in the TestLab PV Modules, Fraunhofer ISE; Geoffrey S. Kinsey, Director of Photovoltaic Technologies, Fraunhofer CSE

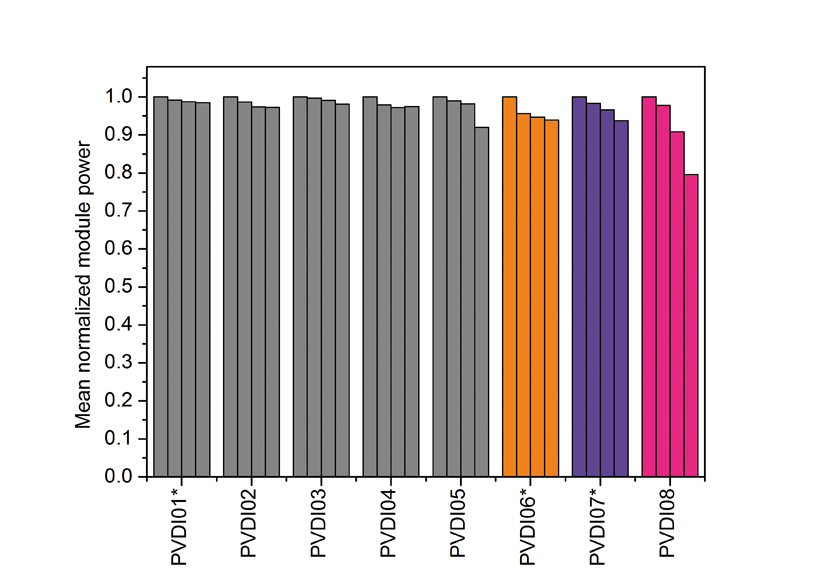

The potential for PV modules to fail before the end of their intended service life increases the perceived risk, and therefore the cost, of funding PV installations. While current IEC and UL certification testing standards for PV modules have helped to reduce the risk of early field (infant mortality) failures, they are by themselves insufficient for determining PV module service life. The goal of the Fraunhofer PV Durability Initiative is to establish a baseline PV durability assessment programme. PV modules are rated according to their likelihood of performing reliably over their expected service life. Modules are subjected to accelerated stress testing intended to reach the wear-out regime for a given set of environmental conditions. In parallel with the accelerated tests, modules are subjected to long-term outdoor exposure; the correlation between the accelerated tests and actual operation in the field is an ultimate goal of the programme. As understanding of PV module durability grows, the test protocols will be revised as necessary. The regular publication of durability ratings for leading PV modules

will enable PV system developers and financiers to make informed deployment decisions. This paper provides summary data for eight module types from the two rounds of testing to date.