By Maximilian Pospischil, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg; Markus Klawitter, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg; Martin Kuchler, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg; Raphael Efinger, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg; Angel Padilla, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg; Harald Gentischer, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg; Markus König, Heraeus Deutschland GmbH & Co. KG, Hanau; Matthias Hörteis, Heraeus Deutschland GmbH & Co. KG, Hanau; Lars Wende, ASYS Automatisierungssysteme GmbH, Dornstadt, Germany; Florian Clement, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg; Daniel Biro, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg; Ralf Preu, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg

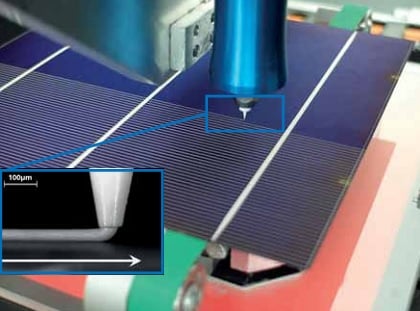

Parallel dispensing technology as an alternative front-side metallization process for silicon solar cells offers the possibility of increasing cell conversion efficiency by 2% rel. by the use of commercial silver pastes designed for screen-printing technology. This efficiency gain is achieved through a significantly reduced finger width, and hence reduced shading losses, in combination with substantially improved finger homogeneities and high aspect ratios that guarantee sufficient grid conductivity at reduced paste lay-down. In this paper Fraunhofer ISE’s development of a parallel dispensing unit that is integrated into an industrial, inline-feasible platform made by ASYS is discussed. A possible industrial application of the dispensing technology is supported by latest results from pilot processing as well as by basic economic considerations