By Matthias Trempa, Iven Kupka, Christian Kranert, Christian Reimann & Jochen Friedrich, Fraunhofer IISB, Fraunhofer THM

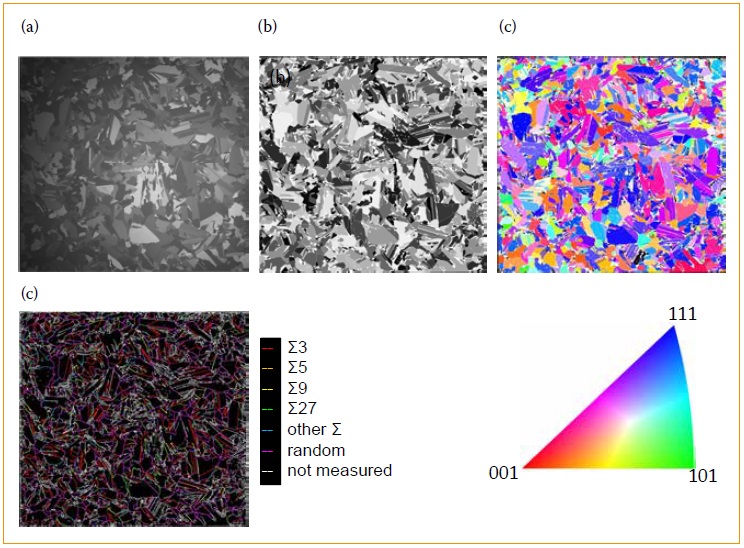

High-performance multicrystalline (HPM) silicon, achieved by nucleation on special seed layers at the crucible bottom, is now increasingly replacing conventional multicrystalline (mc) silicon, which is solidified on the standard silicon nitride coating. The HPM material is characterized by a very fine initial grain structure consisting of small, regularly shaped grains surrounded by a large number of random-angle grain boundaries. These grain structure properties, which differ significantly from those of conventional multicrystalline silicon, lead to a much lower dislocation content in the material, and therefore result in higher efficiencies of the silicon solar cells produced. This paper gives a rough overview of the worldwide R&D activities on HPM silicon in recent years, supplemented by several research results obtained at Fraunhofer IISB/THM. The focus is on the different seeding methods, the grain structure properties and the development of the grain and defect structure over the ingot height, as well as on the main challenges for further improvements in material quality and production costs.