By Filip Duerinckx, Principal Engineer, IMEC; Emanuele Cornagliotti, Research Scientis, IMEC; Angel Uruena, Research Engineer, IMEC; Victor Prajapati, Silicon PV Researcher, IMEC; Patrick Choulat, R&D Engineer, IMEC; Philip Pieters, Director of Business Development for Energy, IMEC; Jef Poortmans, Director of the Solar and Organic Technologies Department, IMEC

A cost-effective and industrial version of the well-known passivated-emitter

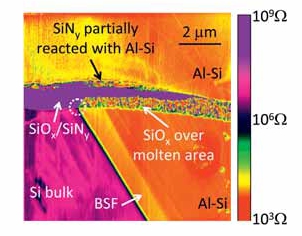

and rear cell (PERC) concept has been developed by imec. The imec i-PERC technology comprises a large-area p-type monocrystalline Si solar cell with, on its front, a homogeneous emitter, a thin thermal oxide layer and fine-line Ag screen-printed contacts; on its rear, the cell has a chemically polished surface, low-cost rear dielectric stack layers and local Al contacts. Yielding certified efficiencies of up to 20% and fill factors of 80%, these cells clearly outperform aluminium back-surface field (Al-BSF) cells. During the development stages, process complexity and additional tool investment were kept to a minimum. It is

therefore believed that this technology can be picked up by companies in a straightforward way as the next-generation industrial solar cell technology.