By Gediminas Račiukaitis, Department of Laser Technologies, Center for Physical Sciences and Technology (CPST); Simonas Grubinskas, Department of Laser Technologies, Center for Physical Sciences and Technology (CPST); Paulius Gečys, Research Fellow, Department of Laser Technologies, Center for Physical Sciences and Technology (CPST); Klaus Zimmer, Senior Scientist and Group Leader, Leibniz Institute of Surface Modification; Martin Ehrhardt, Leibniz Institute of Surface Modification; Anja Wehrmann, Leibniz Institute of Surface Modification; Alexander Braun, CTO, Solarion AG

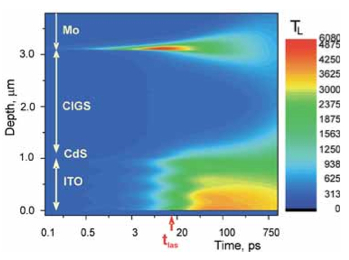

Thin-film solar cells (TFSCs) still hold unlocked potential for achieving both high efficiency and low manufacturing costs. The formation of integrated interconnects is a useful way of maintaining high efficiency in small-scale solar cells by their connection in series to form a module. Laser scribing is widely used for scribing a-Si- and CdTe-based TFSCs to form interconnects. The optical properties of the ternary copper-indium-gallium (di)selenide (CIGS) compound are well suited to the solar spectrum, with the potential to achieve a high photoelectrical efficiency. However, since it is a thermally sensitive material, new approaches for the laser-scribing process are required, to eliminate any remaining heating effects. For flexible CIGS solar cells on non-transparent substrates (metal foils or polymer), the scribing process faces additional challenges. This is one reason why ultrashort laser pulses yield better results in terms of scribing quality and selectivity. The modelling of laser energy coupling and an extensive characterization of laser scribes allow approaches to be developed for laser scribing of CIGS solar cells on flexible polymer substrates. The measured high efficiency of the resulting high-speed laser-scribed, integrated CIGS mini-modules proved the capability of this approach.