By Joris Libal, Research Engineer, ISC Konstanz; Andreas Schneider, Head of the Module Development Department, ISC Konstanz; Andreas Halm, Project Manager, ISC Konstanz; Radovan Kopecek, Head of the Advanced Solar Cells Department, ISC Konstanz

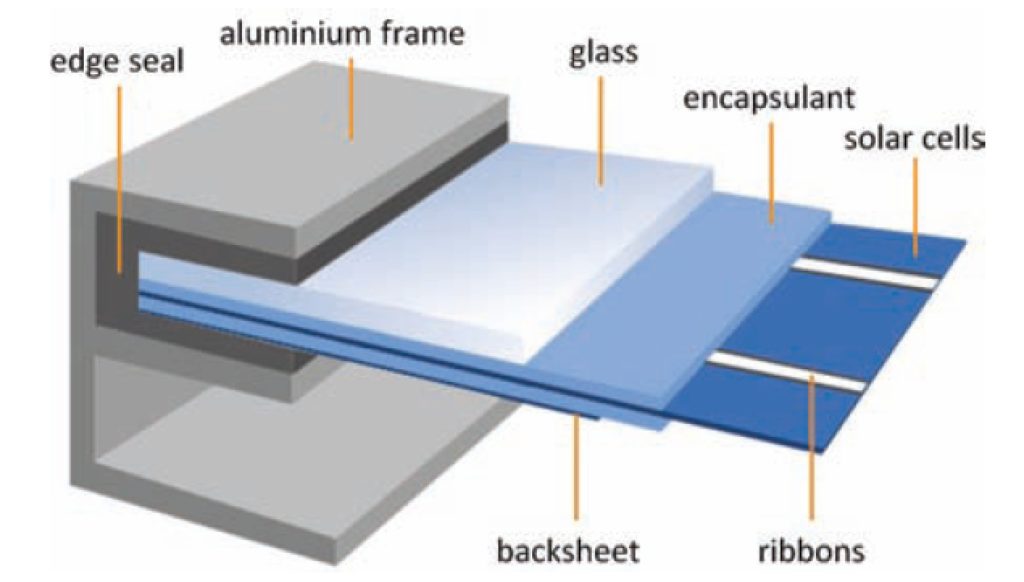

Why change a product which can be sold in high quantities with a large margin? This is one of the reasons why crystalline silicon modules look the same today as they did 30 years ago. In addition, a module has to last for more than 20 years; to change the technology, or even just the material, many complicated, long-lasting and costly tests are necessary. And even after a series of successful tests there is no guarantee of a long-lasting product. Moreover, during the PV crisis starting in 2009, module manufacturers did not have the manpower and budget for introducing novelties into the module market. All the above are reasons why module architecture and materials did not significantly change with time and did not adapt to the introduction of powerful, highly efficient solar cells. After the crisis, however, many module manufacturers became aware that in order to be able to sell modules on the market with a high margin, their products not only have to be cost effective but also must differentiate themselves from the mass product. Consequently high-power, optically nice, colourful, backcontact, transparent, bifacial, light and highly durable modules are now being developed and are gradually being introduced into today’s market. This paper reports on current trends and discusses future developments.