By Jochen Rentsch, Head of the Wet Chemical and Plasma Technologies/ Process Transfer Department, Fraunhofer ISE; Katrin Birmann, Fraunhofer ISE; Tobias Dannenberg, Fraunhofer ISE; Jan Nievendick, Fraunhofer ISE; Antje Oltersdorf, Fraunhofer ISE; Martin Zimmer, Fraunhofer ISE

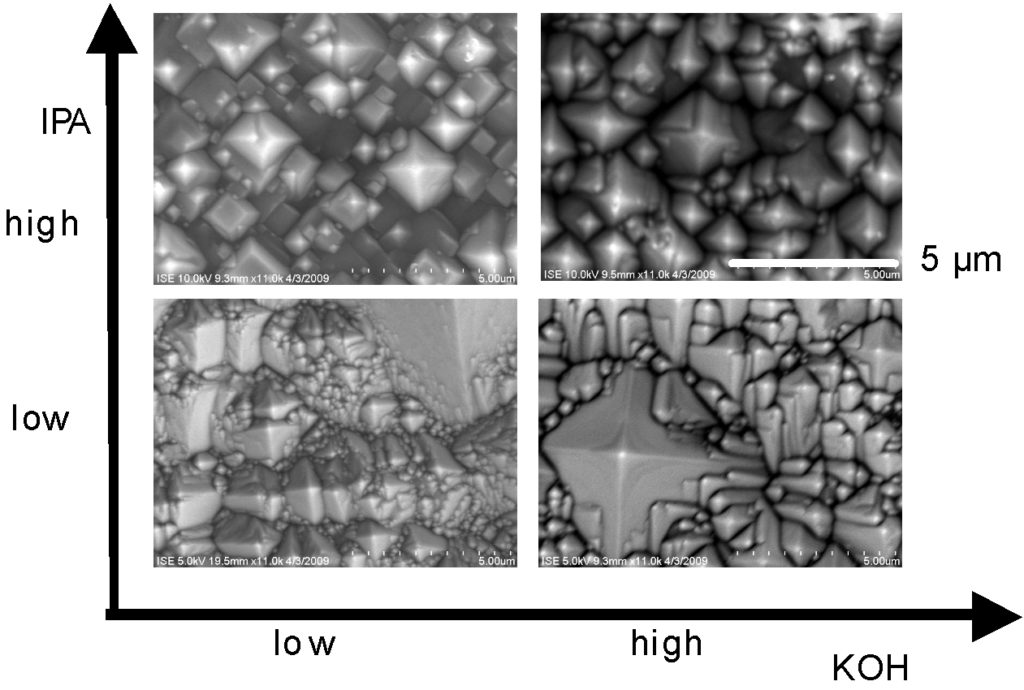

Quality assurance and process control are becoming increasingly important in the industrial production chain to the manufacturing of silicon solar cells. There are a number of relevant wet chemical processes for the fabrication of standard screen-printed industrial solar cells, mainly for texturization and cleaning purposes. While one-component systems like pure HF for oxide-removal are easy to monitor, i.e., by conductivity measurements, typical texturization processes are much more complex due to the number of constituents. For acidic texturization of multicrystalline silicon wafers, typical mixtures involve amounts of hydrofluoric acid (HF), nitric acid (HNO3) and water. It has also been documented that mixtures can be found where additional additives like phosphoric acid (H3PO4), acetic acid (HOAc) and sulphuric acid (H2SO4) have been used [1, 2]. In alkaline random pyramid texturization for monocrystalline wafers, a base like potassium hydroxide (KOH) or sodium hydroxide (NaOH) and organic additives like 2-propanol (IPA) are used [3]. In addition to these processes, recently developed high-efficiency cell concepts require several additional wet chemical process steps like advanced cleaning processes, chemical edge isolation or single side oxide removal processes [4].

In order to obtain continuously stable and reproducible process results and to overcome process operations based on operator experience, a reliable monitoring of the bath concentrations is essential. Such quality control has the potential for significant cost reductions due to optimized durations between replacements of bath mixtures or shortening of processing times. In this context, the application of on-line analytical methods, either by means of chemical, optical or electrical measurement techniques, is of particular interest.