By Milica Mrcarica, Senior R&D Engineer, Photovoltech NV

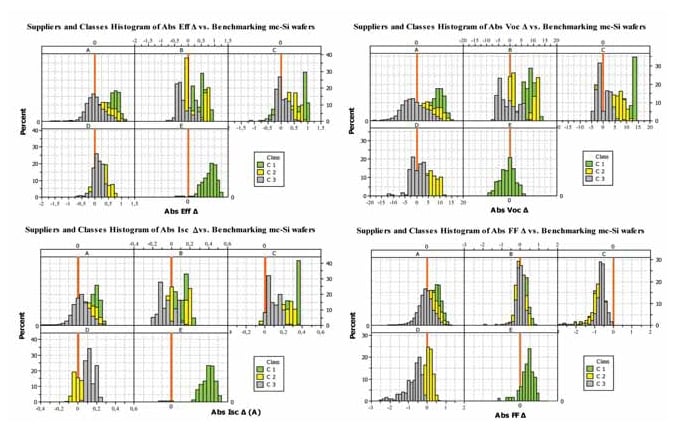

Despite the drop in price of silicon wafers, they are still one of the main factors influencing the cost and performance of Si-based solar cells. These two consequences have initiated a growing commercial interest in mono-cast (castmono, mono-like or quasi-mono) Si wafers, supported by R&D in the areas of material characterization, correlation with cell efficiencies, and mono-cast material use in advanced cell technologies. This paper gives a broad overview and comparison of commercially available grades of mono-cast material from different suppliers. The performance of the material from production in high-throughput screen-printing lines, as well as an analysis of the main material characteristics influencing these results, is presented. A characterization using a lifetime tester and a photoluminescence (PL) imaging tool has shown that not only grain boundaries but also dislocations could cause a drop in cell Voc of more than 15mV. Wafers with large surface areas of Si lattice planes, when processed with anisotropic texturing, could yield an increase in Isc greater than 400mA for 6" substrates, as compared to the isotropic-textured equivalents. Furthermore, when a high-grade mono-cast material processed in anisotropic texturing was compared with CZ mono material from the same supplier and of the same resistivity, light-induced degradation (LID), presented as combined Voc and Isc degradation, was only one-third of that in CZ material. However, although mono-cast material has the potential to increase cell line performance to the same level as that gained by important process and technological improvements, it imposes very high requirements for better material sorting in order to achieve stable cell electrical performance and module aesthetics acceptable to the market.