By Juliane Berghold, Head of R&D, PI-Berlin; Simon Koch, PI-Berlin; Anja Böttcher, Project Manager of Outdoor and Field Projects in R&D, PI-Berlin; Asier Ukar, Project Manager of Outdoor and System-Integrated Projects, PI-Berlin; Mathias Leers, Project Manager, PI-Berlin; Paul Grunow, Member of the Board and Senior Consultant, PI-Berlin

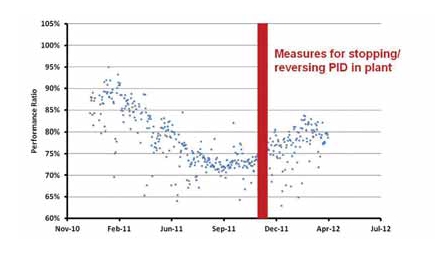

Statistical data on potential-induced degradation (PID) testing at the panel level are discussed in terms of their field relevance and the actual occurrence of PID in the field, since the latter is strongly dependent on both the specific climate and the weather conditions at a certain location as well as on the system configuration realized in a specific power plant. The correlation of outdoor conditions and leakage current is also considered with regard to a suitable standard test for solar panels. Real outdoor data are shown for PID-affected power plants. Indoor and outdoor recovery is demonstrated for PID in real solar plants as well as in lab and outdoor set-ups. Apart from ‘measuring’ PID in suitable tests and in the field, approaches are also presented for the mitigation of PID at the panel and system level.