By E. Suhir, University of California; Dongkai Shangguan, Senior Director, Flextronics Corporation; Laurent Bechou, IMS Laboratory, University of Bordeaux

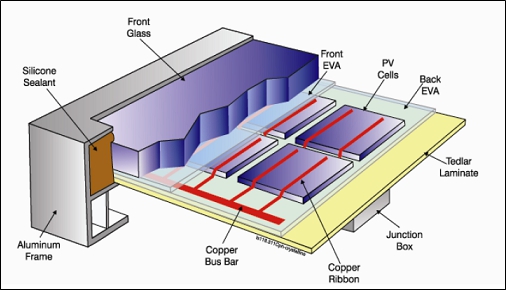

Low-temperature thermal stresses in a manufactured photovoltaic module (PVM) based on crystalline silicon (Si), before the PVM is fastened into a metal frame, are assessed on the basis of a simple, analytical (mathematical), easy-to-use and physically meaningful predictive stress model. The PVM considered comprises the front glass, ethylene vinyl acetate (EVA) encapsulant (with silicon cells embedded into it) and a laminate backsheet. The stresses addressed include normal stresses that act in the cross sections of the constituent materials and determine their short- and long-term reliability, as well as the interfacial (shearing and peeling) stresses that affect the assembly’s ability to withstand delaminations. The interfacial stresses also determine the cohesive strength of the encapsulant material. The calculated data, based on the developed model, indicate that the induced stresses can be rather high, especially the peeling stress at the encapsulant-glass interface, so that the structural integrity of the module might be compromised, unless the appropriate design-for-reliability (DfR) measures, including stress prediction and accelerated stress testing, are taken. The authors are convinced that reliability assurance of a photovoltaic (PV) product cannot be delayed until it is manufactured – such an assurance should be considered and secured, first of all, at the design stage.