By Gerhard Rauter, Member of the Executive Board, Q-Cells SE; Peter Csatáry, Vice President, M+W Zander Group GmbH; Hartmut Schneider, Deputy Manager, M+W Zander Group GmbH; Martin Beigl, Managing Director, M+W Zander Group GmbH

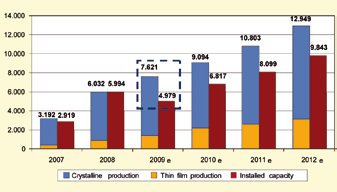

The photovoltaic market is currently experiencing a rapid decline in average selling price per module, resulting in a new era of challenges to reduce the investment and operational costs of manufacturing facilities. Subsequently, PV modules are rapidly gaining acceptance for industrial applications in the renewable energies sector. The PV industry will therefore need to progress toward high volume production of the established process technologies to meet future demand after the current inventory base has been installed. This paper addresses the potential impact of process technology, manufacturing and automation considerations, as well as the appropriate building concepts for large-scale crystalline silicon cell manufacturing. The other inherent advantages and considerations regarding fabs with a capacity approaching one gigawatt peak are also evaluated and discussed based on comparisons between two actual production facilities.