By Verena Steckenreiter, Si Thin-Film Technology Group, ISFH; Arnaud Morlier, Module and Interconnection Technology Group, ISFH; Marc Köntges, Head of Group, Module and Interconnection Technology, ISFH; Sarah Kajari-Schröder, Head of Group, Silicon Thin-Film, ISFH; Rolf Brendel, Director, ISFH

Encapsulants play a crucial role in ensuring the long-term stability of the power output of PV modules. For many years the most popular encapsulation material for crystalline silicon modules has been ethylene vinyl acetate (EVA), which leads the market because of its cost-effectiveness. Innovations in crystalline silicon cell and module technology, however, have changed the requirements that the encapsulants have to meet. A wide range of other encapsulation materials is also available; such alternatives offer improved outdoor

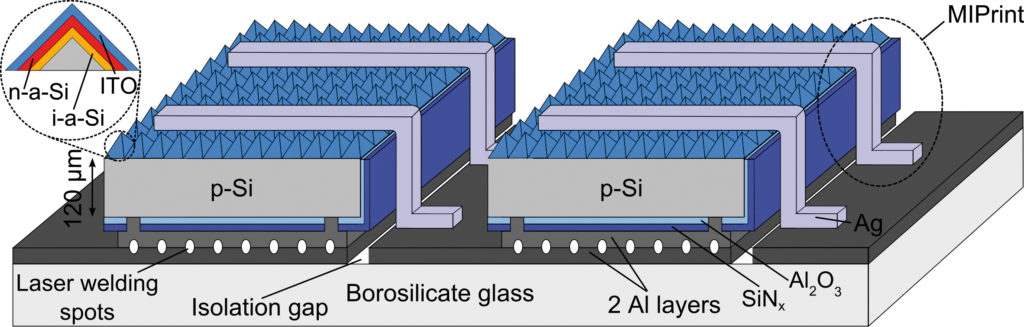

stability and gains in module performance. Furthermore, innovative module concepts that have new sets of requirements are under development. One attractive module concept in particular envisages the attachment of pieces of crystalline Si to the large module glass at an early stage, followed by the processing of the Si cell and the series interconnection at the module level using known processes from thin-film photovoltaics. This so-called thin-film/wafer hybrid silicon (HySi) approach relies heavily on module-level processing of Si solar cells, and is a new field of research. This paper discusses the applicability of silicone encapsulants for

module-level processing and compares their requirements with those of conventional EVA.