By Andreas Lorenz, studied printing technology at t he University of Printing and Media in Stuttgart, Germany, and received his diploma degree in 2006 for his work at manroland AG on printed electronics applications using flexography.; Anna Münzer, studied physics at the Eberhard Karls University of Tübingen, Germany, where she completed her bachelor’s in 2015.; Thomas Ott, received his diploma degree in mechatronics engineering from the University of Applied Sciences Ulm, Germany.; Florian Clement, is head of the MWT solar cells/printing technology group. He studied physics at the Ludwig Maximilian University of Munich and the University of Freiburg, and obtained his diploma degree in 2005; Martin Lehner; Armin Senne; Roland Greutmann; Heinz Brocker; Friedhelm Hage

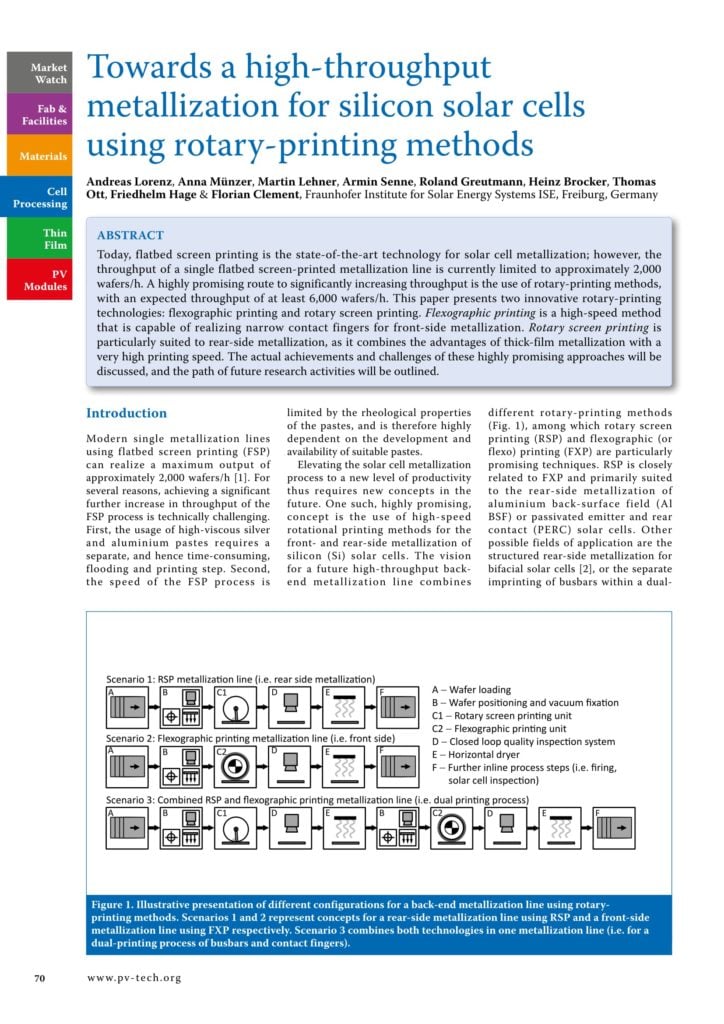

Modern single metallization lines using flatbed screen printing (FSP) can realize a maximum output of approximately 2,000 wafers/h. For several reasons, achieving a significant further increase in throughput of the FSP process is technically challenging.