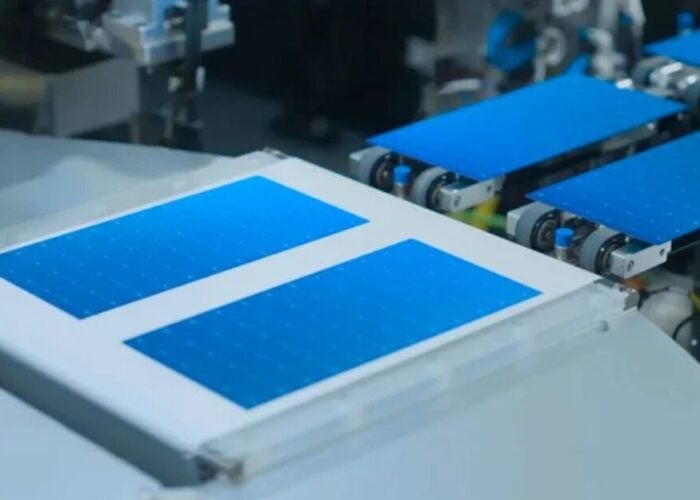

Vesuvius, which provides an extended range of refractory products used in the manufacturing of thin film and polycrystalline solar panels has introduced the ‘SOLAR Crucible MLC,’ a crucible used for the fusion and the crystallization of polysilicon in the manufacturing of mono-like silicon ingots. The system has been specially engineered to match mono-like special requirements.

Problem

Improving the both the high-purity and yield of quasi-mono ingots is key to reducing costs and enable the wider adoption of the technology.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Solution

SOLAR Crucible MLC is a coated ‘Mono-Like’ crucible designed to optimize mono-crystal growth in multi-crystalline ingot growth furnaces leading to higher yield of mono-like wafers per ingot. The crucible combines unique and proprietary composition, geometrical parameters and manufacturing process enabling it to increase the yield of mono-crystal wafers per ingot. In particular, the crucible presents extremely high internal bottom flatness that ensures a perfect seed alignment. Such alignment is critical to prevent undesired multicrystallization at the vertical of seed interfaces and to disrupt the targeted mono-crystal growth. Thermal gradients within the silicon melt are another source of undesired multi-crystallization phenomena during the cycle. To prevent such thermal gradients, SOLAR Crucible MLC is designed to enable high and homogeneous heat convection along the entire bottom surface of the crucible. The crucible also combines unique and proprietary composition and geometrical parameters enabling to reduce the migration of impurities into the molten silicon during the crystal growth process. Such reduced migration of impurities translates into up to 25% bottom red zone reduction and into increased average lifetime of mono-like wafers, according to the company.

Applications

Silicon ingot casting in multi-crystallization furnaces using the mono-cast technology.

Platform

Each SOLAR Crucible MLC is designed to ensure safety in operation and to prevent any leakage. All designs are validated through finite element analysis simulating constraints and deformations in the crucible, using a minimum safety factor of 4. Packaging SOLAR Crucible MLC is available in both industrial and laboratory size depending on customer’s needs.

Availability

September 2012 onwards.