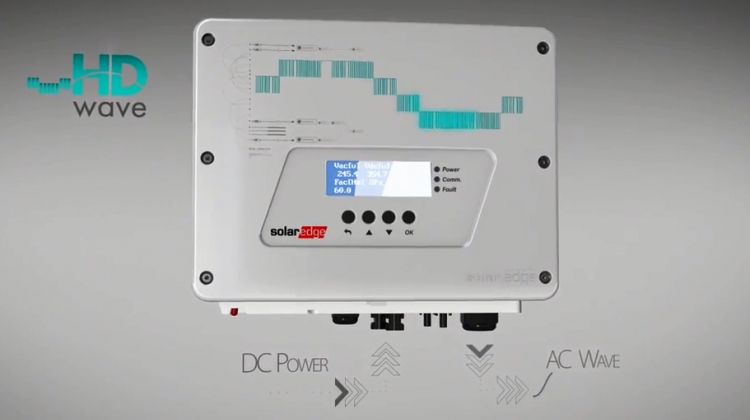

In addition to launching a residential energy management and PV self-consumption package for the home compatible with Tesla’s Powerwall, power optimiser specialist SolarEdge launched a lightweight inverter late last year.

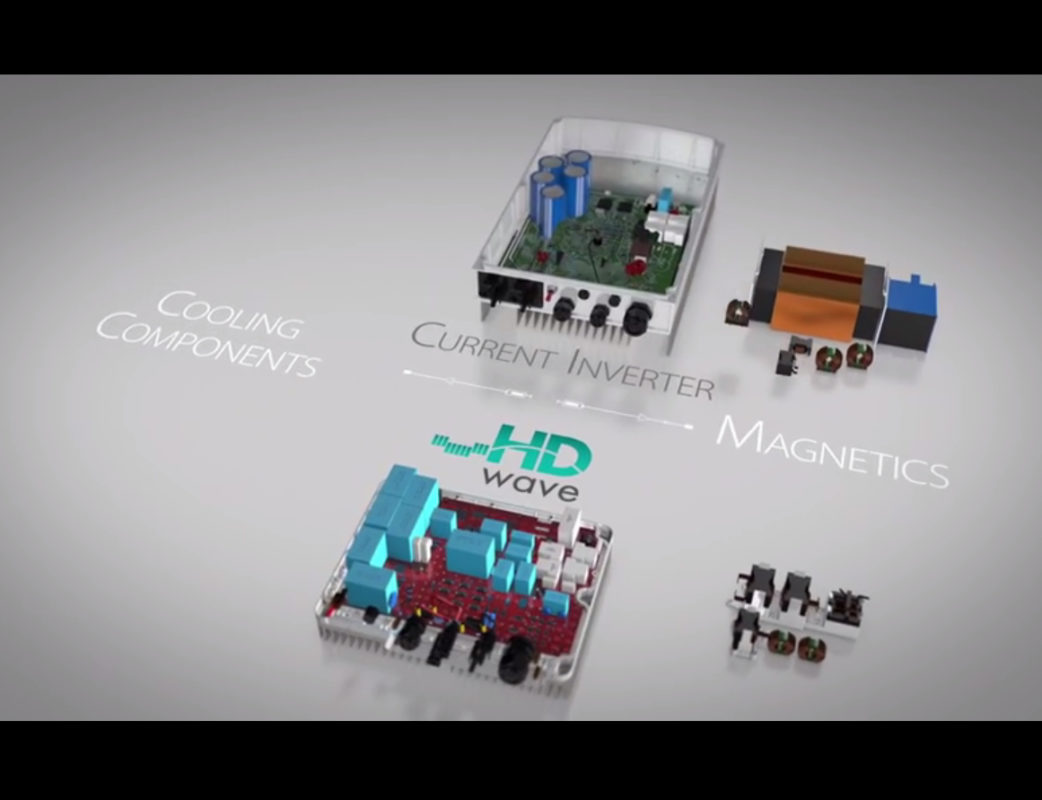

Utilising the Israel-headquartered firm’s new HD Wave technology, the company claimed the new devices can reduce the proportion of magnetic and cooling components significantly compared to other inverters.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

At the time of launch, company vice president of marketing and product strategy Lior Handelsman told PV Tech that the typical inverter weight could be reduced from 22kg down to just 9.5kg using HD Wave. Handelsman even said that SolarEdge could have won the US$1 million cash prize on offer in Google’s ‘Little Box’ challenge to develop a significantly reduced size and weight inverter. PV Tech spoke further with Handelsman about the development of HD Wave.

SolarEdge has always worked closely with installers, including offering training. Have you had any feedback yet on HD Wave and how it could reduce labour costs and hassle?

They say it’s much easier to install because of the weight, but the real thing here [with HD Wave] is that the aim of the technology from the very beginning was to find ways to take out of the inverter the heavy, copper-bearing components, inductors and magnetics, cooling elements which are basically an aluminium block. Today in inverters they are 50% of the cost of the inverter. So we have this electronic device, the inverter, the electronic circuitry is not much of the cost and a lot of the cost lies in the heavy copper, iron and aluminium costs.

So it’s about reducing the non-electronic components?

So the technology is a way to reduce magnetics by a factor of 16 and the aluminium parts by a factor of 2.5. Now the electronics become the main cost and performance driver and we all know that electronics evolve much faster than physical materials.

So it's not only a little [step], but we think in two years we can leap again when we have more processing power and more advanced components. This means that inverters can evolve at the rate of electronics and not at the rate of mechanics.

How does HD Wave replace those heavy metallic parts?

If you look at what others are doing, most of the inverter companies are trying to replace the switching elements, with more advanced switching components like silicon carbide and gallium nitride.

These basically improve the performance of inverters but they don’t rid the inverters from the cooling issue – they help with the cooling a little bit – but they don’t rid the inverter from the large heavy magnetics and they don’t have such a strong impact on the cooling element.

We didn’t want to go to these exotic switching elements, that come from a single vendor, we stayed with very common silicon switches, but with using algorithms, we found a way to switch with magnetics and aluminium.

I’ve heard SolarEdge say this could be like the ‘flat screen revolution’ in televisions, but is it also analogous to computing? I’m thinking of the advent of microchip processors, which drastically reduced the size and weight of computers in 80s and 90s.

It is similar in some ways, but I would not use that analogy, because other things about it are not similar. The introduction of microelectronics was a huge revolution, because it allows you to use the same components exactly, only they were much much smaller in size.

But it also demanded a huge technological leap in terms of production capability. So you had to develop the entire microelectronics industry with production processes and all that. So essentially, the microelectronics revolution is a manufacturing revolution, more than anything else. HD Wave is an ‘algorithmical’, topology revolution. The manufacturing process stays the same for the way you make the inverter. It’s just a different topology that requires a lot of computational power instead of some switching of DC to AC.

That’s why we compare it to the flat screen. That was basically standard electronics, using LCD which was available in LCD screens for years. They just found a way to make huge flat screens. Every component was something else which was already evolved. Microelectronics was an evolution of manufacturing – how to fit all the same components into one small device.

We’ve often heard about how competitive the inverter market is becoming worldwide. I guess if you’re planning to “leap again” in two years, you must already have your eye on the industry’s next likely moves?

Everyone has to keep pushing forward, because there is constant pressure, price pressure, from low cost manufacturing areas. They can always evolve and make the product better and better simply by learning what others are doing.

If you do not innovate, really innovate with new technologies, you will not survive. Because the market, maybe not just for inverters but the whole solar industry will eventually become commoditised, everyone is going to make solar power. We want everyone to eventually make solar power and in a market that is very commoditised, the only way to survive is to innovate.

Everyone else in the entire industry is trying to innovate around switching technologies, silicon carbide, gallium nitride, and we took a different route. We are innovating around topology and algorithms. We believe that this is the way to go. Others think otherwise.

And by the way, the minute silicon carbide and gallium nitride are going to be common [switching elements] we can use them also. Once those are common enough and work well, we can just add them to the inverter.