The lack of standardisation and verification in the technical specifications of photovoltaic (PV) components is a challenge that is often underestimated in the solar industry.

In a sector driven by data, even minor discrepancies in module or inverter parameters can have significant implications, affecting simulation accuracy, PV design decisions, financial modelling and, ultimately, the long-term performance and bankability of solar projects.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Below, I explore how unverified PV component data can compromise project outcomes and why the industry must adopt more rigorous and standardised approaches to PV component data management. Doing so will help PV developers and investors ensure more accurate energy yield predictions, optimise PV performance and improve financial feasibility of their PV assets.

The prevalence of inconsistencies

PV component specifications are typically stored in PAN and OND files, plain text formats that are not standardised and easily tampered with. These files are widely shared, often without any form of verification, resulting in multiple versions of the same product circulating throughout the industry. With no single source of truth, developers may unknowingly base system designs on incorrect or outdated component data.

These inconsistencies have a direct impact on simulation outcomes. If the technical parameters do not accurately reflect the actual performance of a module or inverter, simulations may yield energy predictions that are overly optimistic or misleading. In a market increasingly driven by performance guarantees and financial return models, this disconnect presents a significant financial risk.

Moreover, as the variety and complexity of PV technologies continue to grow – driven by rapid innovation in solar technology and module materials – the risks associated with inaccuracies in PV component data are only increasing.

Skewed simulations, suboptimal design decisions

Reliable data is essential at every stage of solar project development, but it is particularly critical during system design and performance simulation. These phases depend on accurate modelling of how a given set of PV technologies will perform under site-specific conditions, including temperature, irradiance, wind and other environmental variables.

Using unverified or generic component data introduces a margin of error that can lead to poorly optimised system configurations. For example, differences in spectral response between monocrystalline and polycrystalline modules, or the presence of specific coatings, can significantly affect energy yield. This is particularly significant in regions with variable solar conditions or strong interannual variability.

Several studies of simulation models highlight this issue, showing a strong correlation between the accuracy of component specifications and the reliability of yield predictions. The implications are serious: financial losses caused by overly optimistic energy yield estimates can undermine investor confidence, delay project approvals and ultimately affect long-term revenue forecasts.

The case for a verified, industry-wide component database

To address this growing concern, the solar sector must bring greater transparency and rigour to PV component data management. The industry needs a standardised, centralised and verified database of PV modules, inverters and other components that developers can rely on with confidence.

Such a database should:

- Include validated specifications from manufacturers and third-party certifiers.

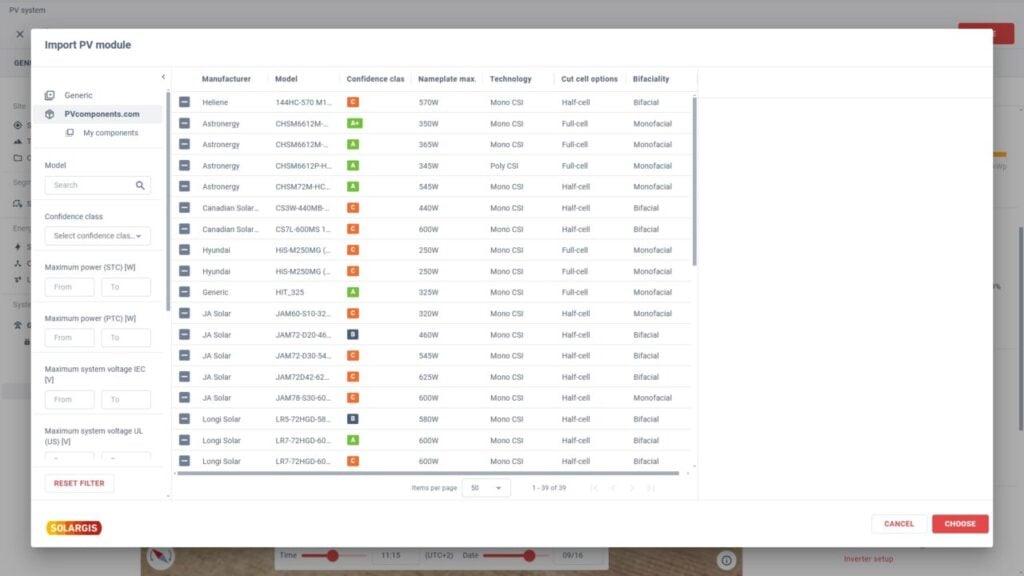

- Assign confidence levels to component data based on verification rigour.

- Be maintained in a format compatible with modern simulation software tools.

- Be accessible to all stakeholders, including developers; engineering, procurement and construction firms (EPCs); banks and auditors.

The introduction of confidence classes – indicating the reliability of data based on automated checks and expert validation – can help quickly convey the trustworthiness of specific component data. Assigning a confidence class, such as A, B, C or Unknown, to a PV component based on the completeness and reliability of its data would streamline the due diligence process and reduce the time and costs of technical validation.

Platforms like Solargis’ PV Component Catalog are making strides in this direction by offering a web-based, collaborative and rigorously validated platform for PV components.

As solar energy continues to play a central role in the clean energy transition, the financial and technical performance of solar projects must be underpinned by reliable data, particularly when it comes to PV component specifications. Inaccuracies in these inputs can lead to flawed simulations, poor system design and ultimately compromised project economics.

The solar industry can no longer afford to overlook this challenge. By embracing standardised data formats, verified component databases and rigorous validation methodologies, developers and investors alike can ensure that solar projects are not only technically sound, but also bankable, resilient and built for long-term success.