The International Solar Energy Research Center Konstanz e.V. (ISC Konstanz) has signed a technology transfer agreement with PV module assembly equipment supplier based in Finland for R&D centre’s advanced ‘BiSoN’ (Bifacial Solar cell On N-type) and ZEBRA (diffused n-type IBC) solar cell technology.

Valoe noted that it had acquired a solar cell production line from Megacell S.r.l., which was under liquidation, and a producer of bifacial n-PERT solar cells in Italy based on the ISC Konstanz technology.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

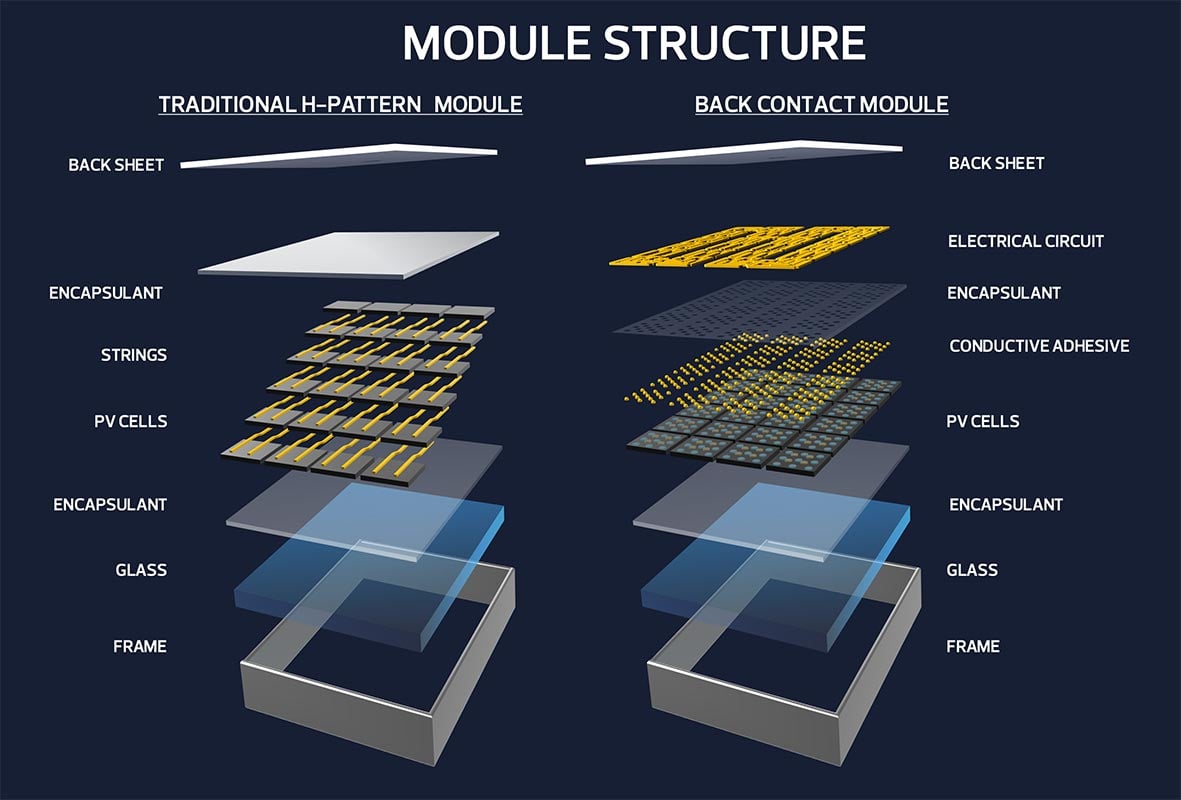

Dr. Radovan Kopecek, CTO at ISC Konstanz and Managing Director of Advanced Cell Concepts: “We are very pleased to continue assisting you in developing ZEBRA further. Together with Valoe´s back contact module technology such a module using ZEBRA is very powerful at low costs. Valoe has, as one of the first companies in the world, developed a mass scale module manufacturing technology which makes the implementation of back contact solar cells into the module extremely simple, cost effective and with high yield. Further, Valoe’s technology makes it possible to use thinner solar cells. The PV market is now ready for such modules build on IBC cell technology for many new applications.”

Valoe also noted that it planned to transfer part of the production line to PV manufacturer Soli Tek Cells’ production facility in Lithuania to undertake volume production of IBC solar cells for customers of Valoe, sometime in 2019.

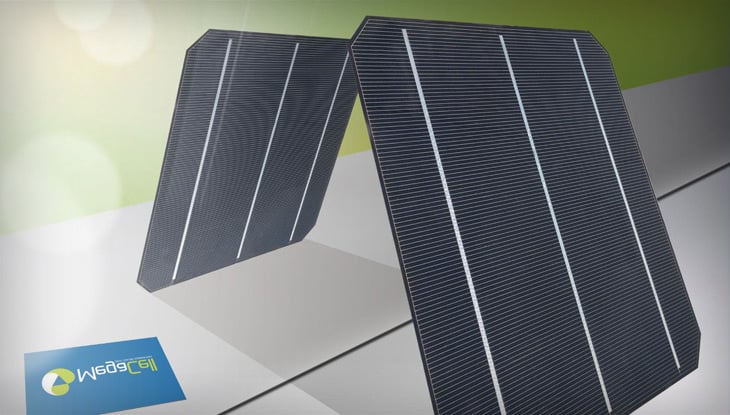

ZEBRA based IBC cells have reach conversion efficiencies of more than 23% and module efficiencies would be supported Valoe’s unique back contact module technology that can also handle ultra-thin N-type mono wafers, lowering production costs.