Utility-scale solar projects continue to expand in both capacity and footprint, but this growth brings new challenges to engineering, procurement and construction (EPC) teams and system designers.

As a case in point, projects spanning hundreds of acres and hundreds of megawatts require extensive conductor runs, increasing the need for voltage drop mitigation. Every fraction of a percentage in voltage drop translates to lost energy, lost revenue and lower long-term profitability, in addition to other hidden costs caused by potential damage to equipment.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Since voltage drop is a decrease in voltage that occurs as current flows through different components in a solar system, some countermeasures include oversizing conductors, shortening cable runs or increasing system voltage. These are standard PV engineering best practices, established in NEC and IEEE guidelines. These options are also costly, increasing materials costs and installation complexity, and offsetting some of the benefits of minimising voltage drop in the first place.

An efficient alternative is proving its value in voltage drop abatement – optimising electrical balance-of-system (eBOS) architecture. For example, by selecting recombiners over DC disconnects, teams can minimise connection points, reduce resistive losses and lower voltage drops. As a result, the eBOS architecture improves energy yield and operational efficiency while also delivering measurable cost savings.

Unlocking value in utility-scale project planning, construction and execution

Design efficiency is even more imperative as large-scale PV deployments grow in size and capacity. DC voltages are increasing to 2000V and beyond, requiring additional focus on building future-ready systems. On top of that, escalating power demands are adding additional strain to aging grids and limited natural resources.

While solar energy is highly productive and cost-competitive with fossil fuels, there are still untapped opportunities for optimisation. Owners, developers and EPCs have ongoing opportunities to meet demand through innovative design improvements that reduce costs while boosting performance, and eBOS unlocks value across each lifecycle phase:

Design phase

Considering eBOS architecture in early planning stages is one way to optimise design, installation, and production. While historically often overlooked at this juncture, integrating eBOS infrastructure optimisation into initial discussions and designs can yield both short- and long-term value.

Construction phase

With eBOS optimised, stakeholders see immediate benefits from reduced materials and streamlined installation, while setting the stage for improved performance across the lifecycle of a project.

Operations & maintenance phase

In addition to reducing voltage drop, strategic eBOS architecture offers asset reliability and simplified maintenance, easing the responsibilities and costs of O&M.

Orange Grove Solar Site: eBOS streamlining in practice

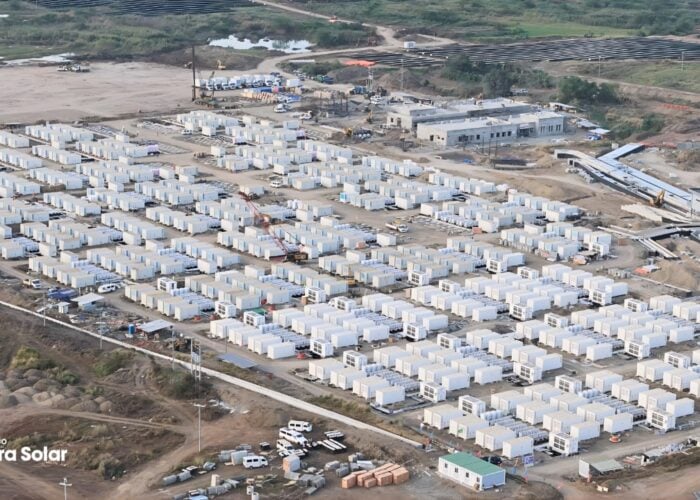

The Orange Grove Solar Site, located near Corpus Christi, Texas, is a landmark project that showcases the importance of eBOS architecture in preventing voltage drop.

To mitigate the risk of voltage drops at its Orange Grove site, the project engineering team at Qcells EPC explored an eBOS solution to improve energy production while saving costs. The team looked at two trunk bus-compatible box options – the disconnect enclosure and the recombiner – and weighed the pros and cons of each.

Disconnect enclosure: one trunk in, one output

- Pro: O&M or servicing teams can turn off one individual trunk.

- Con: more boxes are required as there is a box per trunk.

Recombiner: multiple trunks in, one output

- Pro: fewer boxes needed, which translates to cost savings and less maintenance; fewer connection points help reduce voltage drop.

- Con: O&M or servicing teams need to turn off all trunks feeding into the box.

After assessing the site, the team chose recombiners for the Orange Grove project. This option helped reduce voltage drops with fewer boxes and, therefore, fewer connection points, ultimately reducing related material costs by 22%.

Results

The Orange Grove project required a maximum voltage drop of 1.5%, meeting industry standards. The team’s choice of recombiners successfully lowered the voltage drop to 0.5% – a substantial improvement that exceeded typical performance benchmarks.

With fewer electrical boxes on-site, the site has simplified and less time-consuming maintenance needs. The streamlined installation process kept the project on time and on track. Wiring was trenched and buried, making routine mowing far more efficient.

From a budget perspective, the choice to use 216 recombiner boxes rather than 432 DC disconnects resulted in 216 fewer boxes installed and an 18% saving in cost. Over the long term, with fewer boxes and connection points, the reduced voltage drop enabled peak energy production, improving revenue and profitability.

The evolving role of eBOS

eBOS architecture is evolving to become more than the sum of its electrical components. Beyond circuit breakers and switches, eBOS is a strategic tool that drives value creation for utility-scale solar projects. Owners, developers and EPCs are reaping rewards in the form of accelerated on-site installation, reductions in costly voltage drops and better lifecycle return on investment. While eBOS is typically on the back burner in planning, it’s time for teams to bring it forward as an approach to better performance and a solution to voltage drop. Doing so will maximise performance and continue bringing solar growth into our collective clean energy future.

Author: Jason Coleman is director of business development, Terrasmart