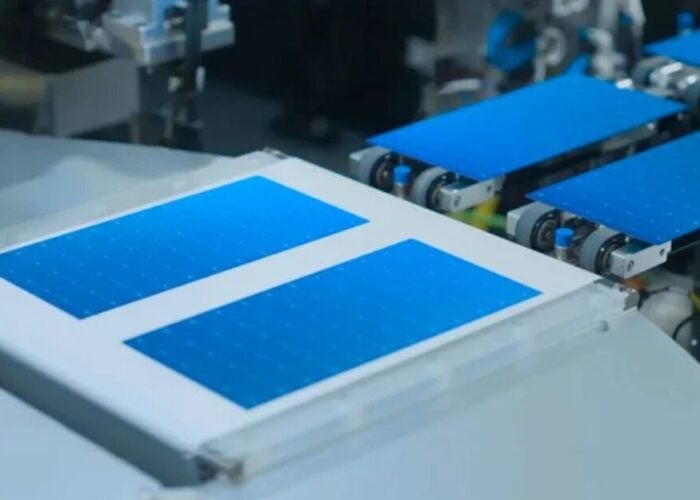

In a planned three-year effort to reduce the cost of producing crystalline silicon solar cells by reducing and the amount of Si/Watt that is needed by half and boost conversion efficiencies to approximately 20%, SCHOTT Solar has joined IMEC’s newly launched silicon photovoltaics industrial affiliation program (IIAP). The program is expected to see silicon solar cell manufacturers, equipment and material suppliers collaborate and share intellectual property, talent, risk and costs involved in the project.

“In the highly dynamic market of solar power, short time to market for new products is essential,” noted Dr. Martin Heming, Chief Executive Officer at SCHOTT Solar AG. “Therefore, SCHOTT Solar is pleased to announce that the company has joined the high-level IIAP R&D program at IMEC, the leading research institute in the field. We support IMEC’s ambitious goals and their work towards creating success their partners.”

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

IMEC’s program will explore both wafer-based bulk silicon solar cells and epitaxial cells. On the bulk-silicon solar cell sub-program, generic process technology will be developed that will improve the efficiency of the cell while reducing manufacturing costs.

The active silicon layer thickness will be reduced from 150µm down to 40µm. To meet efficiencies of about 20%, alternative back-side dielectric stacks and interdigitated back-side contacts (i-BC) will be introduced in thin-wafers using a PERL-style (PERL = passivated emitter and rear local back surface field) concept in an industrial process flow. Cell module integration will be investigated since reduced wafer thickness will impose specific integration requirements.

“Building on our 25 years track record in silicon solar cells and our successful experience with Industrial Affiliation Programs on CMOS scaling, we are confident that we will provide our partners a dynamic research platform for accelerated process development;” said Jef Poortmans, Program Director Solar+ at IMEC.