Solyndra has signed a long-term sales contract with Carlisle Energy Services, a newly formed division of Carlisle Construction Materials, to supply its proprietary cylindrical-tube-based copper-indium-gallium-(di)selenide (CIGS) solar panels for rooftop applications. The multiyear sales contract–said to be worth up to $320 million– brings Solyndra’s total announced order backlog to more than $1.5 billion.

“The Solyndra PV system is a natural fit for our Energy Star-certified, cool roof systems,” said John Altmeyer, CEO of Carlisle Construction. “When installed on Carlisle’s white reflective TPO (thermoplastic polyolefin) roofing membrane, the output of the Solyndra PV system increases up to 20%.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

“The installation of a Solyndra system is exceptionally quick and economical, and can be easily accomplished by a roofing contractor along with the installation of an insulated cool roof. Together with Carlisle’s large network of roofing installers, we can rapidly deploy systems which provide both energy conservation and low-cost solar electricity generation.”

Insulated cool roofs, made of highly reflective and emissive materials, lower daytime air-conditioning electricity usage by reflecting away sunlight and heat, according to the companies. The rapid adoption of cool roofs in the Western and Sunbelt states has been helped by the support of the U.S. Department of Energy’s Energy Star program and by the California Title 24 Energy Standard, which prescribes cool roofs to be employed whenever low-slope commercial roofs are built or replaced.

Solyndra says its PV system, which is designed specifically for commercial rooftops, benefits from installation on a cool roof because of the collection of reflected, direct, and diffuse light. The airflow through Solyndra’s panels allows such roofs to remain much cooler than with other PV systems.

The CIGS TFPV company also claims that its lightweight, nonpenetrating system eliminates the negative impact on roof life and performance associated with either penetrating or heavier, ballasted PV systems and facilitiates easy removal of the panels for roof maintenance or redeployment of the panels.

“This agreement capitalizes on the Solyndra system’s benefits for reflective commercial rooftops,” noted Chris Gronet, Solyndra CEO and founder. “As we enter this new channel, we are excited to work with Carlisle and to extend their leadership position serving the needs of commercial buildings owners.”

Solyndra’s senior director of marketing, Mike Grunow, would not verify to PV-Tech the accuracy of other press reports that state the Carlisle deal will be for 100 MW of panels over five years.

He said that Carlisle, which he calls a “market leader when it comes to single-ply membrane roofing” and has “more than 3500 global installation partners,” is “actively developing customers” for the Solyndra products and will be discussing the TFPV systems at the Greenbuild International conference taking place this week in Boston.

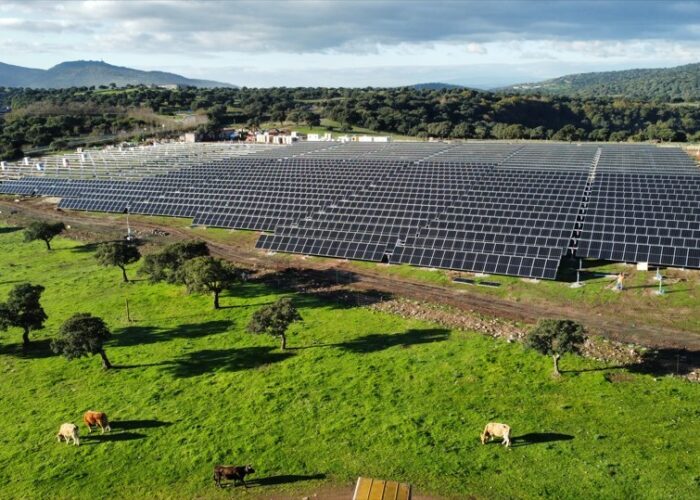

Carlisle recently inaugurated a commercial-scale 50-KW Solyndra PV system on the roof of its TPO manufacturing site in Tooele, UT (see accompanying photo), according to the company’s marketing communications manager, Tony Matter.

“The system was installed last week in one day,” he told PV-Tech in an email, adding that the firm also has a 3-KW test system in Tooele and a similar-sized system at one of its Carlisle, PA, facilities.

Solyndra’s Grunow confirmed to PV-Tech that Carlisle’s two test systems are part of the TFPV panelmaker’s network of 15 beta sites operating in various locations. He noted that “things are going very well in regards to the expected performance” of the panels at the test sites, each of which are outfitted with “highly accurate weather instruments” that have been collecting key data for Solyndra.

Solyndra will manufacture the CIGS panels at its 110-MW front- and back-end production facilities ramping up in Fremont and Milpitas, CA.

Grunow told PV-Tech that the company’s fab lines “are not fully booked” and that there are “significant capacities available.” He would not comment on the specific timing of the groundbreaking for the firm’s Fab 2 to be built in Fremont, noting that Solyndra “was not in jeopardy of pushing out any commercial commitments.”

(To read more about Solyndra and its emergence from stealth mode, check out the recent three-part PV-Tech blog series on the company here, here, and here.)