As commercial PV systems are becoming increasingly prevalent, the competition is increasing in terms of the system return on investment (RoI). One method to improve system RoI is to decrease the CAPEX/upfront costs of the system. Since modules and inverters are decreasing in price, Balance of System (BoS) costs, which make up about 10% of commercial rooftop costs, have been identified as the next option for decreasing these CAPEX/upfront costs.

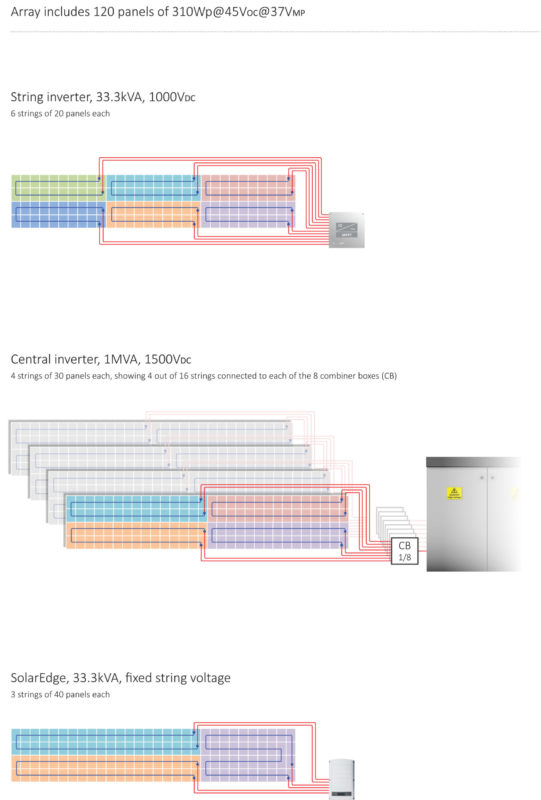

For instance, an array of 120 modules will typically be installed in four strings of 30 modules, and the “homerun” cables could be around 335 feet for each array. In addition, a fuse combiner box would be needed to connect all of the strings. Installing strings that are twice as long, would reduce the number of strings and therefore the amount of required cables and eliminate the need for a fuse combiner box. Because of the potential for cost savings, the industry has begun the race towards enabling longer strings.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Understanding that longer strings can improve the bottom line of the system is only half the battle. Knowing how to technically increase string length is much more complicated. There are two standard ways to increase string length. The first way to increase string length is to reduce the maximum operating voltage of each module. This is done by using certain types of MLPE technology.

An example of this would be a 72-cell (280W peak module), with 45 open circuit voltage. A traditional system with 1000V would allow for 22 modules in a string. However, a system with a reduced maximum panel voltage of 35 would allow for a string of 28 modules. It is important to note that reducing panel voltage does not necessarily mean clipping of power. While this is a 30% increase in string length, the commercial market needs a more competitive solution.

The second way to increase string length is to change the current code and increase inverter input voltage to 1500V, which is a new direction that is currently being introduced to the market. This higher voltage allows for strings as long as 50% more than those of 1000Vdc. In order to implement this, components of the system all need to comply with 1500V, such as the modules, inverters, cabling, and connectors.

While longer strings offer an important advantage for commercial systems, this specific direction suffers from numerous disadvantages and limitations, such as higher component costs, more difficult sourcing, safety concerns, electrical codes, equipment availability, and unknown effects to modules, such as potential induced degredation (PID). Additionally, working at 1500V requires special, non-standard testing equipment (megger, iv-curve, etc.), which is also more expensive and harder to source. Furthermore, higher voltage systems pose higher safety risks and added complexity as in most countries they require specially qualified electricians and special regulatory approvals.

A completely different way to reach longer strings is with fixed-string voltage.

Fixed voltage mode is an advanced operating mode for string inverters. It requires power optimizers to match current level drawn from the inverter, while the inverter maintains string voltage at optimal voltage for DC/AC conversion – regardless of string length or temperature. This means that string length is no longer governed by voltage, but by power. And in fact, it allows for 100% longer strings than standard string inverters, while also keeping the voltage below 1000. Using the same components as mentioned in the previous example, a 1500V inverter could allow up to 45 modules. This is a 15 panel increase over a traditional 1000V system. However, a fixed-string voltage system, like SolarEdge’s solution, can increase string length to a total of 60 modules, in this example.

Increasing string length is not the only impact that inverter selection has. In fact, it reaches far past this aspect. Approximately 25-30% of total costs of commercial systems originate from inverter selection. In terms of upfront expenses, inverter selection impacts Electronic BoS, inverter, and labour costs. But in terms of ongoing costs, the inverter also impacts operation and maintenance activities. Systems that have reduced maximum module voltage require module-level power electronics, so high-resolution monitoring is available, even though the strings do not benefit from a significant gain in length. On the other hand, 1500V systems which have a better improvement in string length, still use a standard inverter without module-level management or power electronics. This is why the fixed-string voltage inverter system is the best of both worlds – it offers longer strings and module-level management and monitoring. This not only helps to reduce O&M costs, but also increase system uptime and energy yield, thus further increasing revenue.

So, while 1500V systems are a new technology that the market is betting on to offer longer strings, a smarter choice is fixed-string voltage inverter systems that have already been field proven.

Lior Handelsman founded SolarEdge in 2006 and currently serves as vice president, marketing and product strategy where he is responsible for SolarEdge’s marketing activities, product management and business development.