By Thorsten Dullweber, R&D Group Leader, Institute for Solar Energy Research Hamelin (ISFH); Christopher Kranz, R&D Group, Institute for Solar Energy Research Hamelin (ISFH); Birgit Beier, Process Engineer, Institute for Solar Energy Research Hamelin (ISFH); Boris Veith, Scientist, Institute for Solar Energy Research Hamelin (ISFH); Jan Schmidt, Head of the Photovoltaics Department, Institute for Solar Energy Research Hamelin (ISFH); Björn Roos, Solar Product Manager, Singulus Technologies AG; Oliver Hohn, R&D Department, Singulus Technologies AG; Torsten Dippell, Project Manager, Singulus Technologies AG

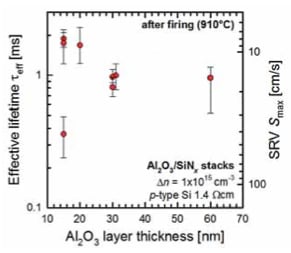

The passivated emitter and rear cell (PERC) is considered to be the next generation of industrial-type screen-printed silicon solar cell. However, only a few deposition methods currently exist for rear passivation layers which meet both the high-throughput and low-cost requirements of the PV industry while demonstrating high-quality surface passivation properties. This paper presents an evaluation and the optimization of a novel deposition technique for AlOx passivation layers, applying an inductively coupled plasma (ICP) plasma-enhanced chemical vapour deposition (PECVD) process. High deposition rates of up to 5nm/s, as well as excellent surface recombination velocities below 10cm/s after firing, are possible using this ICP AlOx deposition process. When applied to PERC solar cells the ICP AlOx layer is capped with a PECVD SiNy layer. Independently confirmed conversion efficiencies of up to 20.1% are achieved for large-area 15.6cm x 15.6cm PERC solar cells with screen-printed metal contacts and ICP AlOx/SiNy rear side passivation on standard boron-doped Czochralski-grown silicon wafers. The internal quantum efficiency (IQE) reveals an effective rear surface recombination velocity Srear of 110±30cm/s and an internal rear reflectance Rb of 91±1%, which demonstrates the excellent rear surface passivation of the ICP AlOx/SiNy layer stack. Currently, the ICP AlOx deposition process is being transferred from the ISFH laboratory-type tool to the Singular production tool of Singulus Technologies in order to commercialize this novel deposition process during 2012.