By Wenjin Xia, Development and Production Manager, Jolywood (Suzhou) Sunwatt Co., Ltd; Yuzheng Zhang, Vice President, Jolywood (Suzhou) Sunwatt Co., Ltd; York Yu, Senior Technical Advisort, Jolywood (Suzhou) Sunwatt Co., Ltd; Hong Liu, Postdoctoral Student, Institute of Solar Energy, Shanghai Jiaotong University; Wenzhong Shen, Director and Professor, Institute of Solar Energy, Shanghai Jiaotong University, Shanghai; Jianwei Lin, Founder & President, Jolywood (Suzhou) Sunwatt Co., Ltd

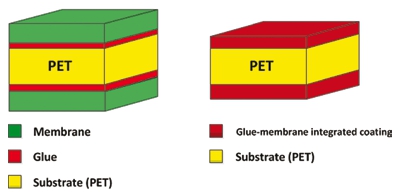

This paper presents a novel glue-membrane integrated backsheet specifically for PV modules, which has been designed and fabricated by utilizing a flow-tangent cast roll-to-roll coating process combined with a plasma technique. Polyethylene terephthalate (PET) is adopted as a substrate and is surface activated and etched by atmospheric plasma. Then a special coating formulation containing reactive fluoropolymers is applied to both sides of the PET, followed by thermal curing, resulting in a glue-membrane integrated coating layer with a polyurethane structure. Finally, a monolayer of silane molecules is grafted onto the surface via plasma-enhanced deposition to provide the surface medium with surface energy, rendering excellent long-term adhesion to ethylene vinyl acetate (EVA). Scanning electron microscope (SEM) images have revealed that plasma etching and activation significantly improves compatibility between the PET and the coating layer, resulting in a tight and strong integration between the two. It has also been confirmed by SEM that the obtained novel backsheet integrates the glue layer and the membrane layer perfectly. There is no clear boundary between the two layers, distinguishing the novel backsheet from the conventional layer-by-layer laminated backsheet. The unique glue-membrane integrated structure has already been demonstrated by many practical applications under harsh environmental conditions to have significant advantages over other backsheets regarding delamination, blistering and discoloration. Furthermore, the novel backsheets showed excellent barrier properties, weatherability (85°C, 85% RH, 1000h), mechanical properties and electrical isolation properties. Because it is a promising photovoltaic material, the novel backsheet has already been widely used in China for PV module encapsulation and has obtained extensive praise from customers.