By Thomas Kaden, studied applied natural science at TU Bergakademie Freiberg and received his Ph.D. in physics in the photovoltaics group of Prof. H.J. Möller.; Elena Ershova, holds a diploma in information technology and systems from TU Wolodga (Russia) and performed the majority of experiments presented here during her bachelor thesis at Fraunhofer THM.; Marcel Fuchs, worked as an operator in wafer and solar cell production and was production supervisor of a wafering company before he joined Fraunhofer THM as senior technician in wafering in 2012.; Rajko B. Buchwald, studied applied natural science at the TU Bergakademie Freiberg. He received his Ph.D. in 2010. In 2010 he joined Fraunhofer THM in Freiberg.

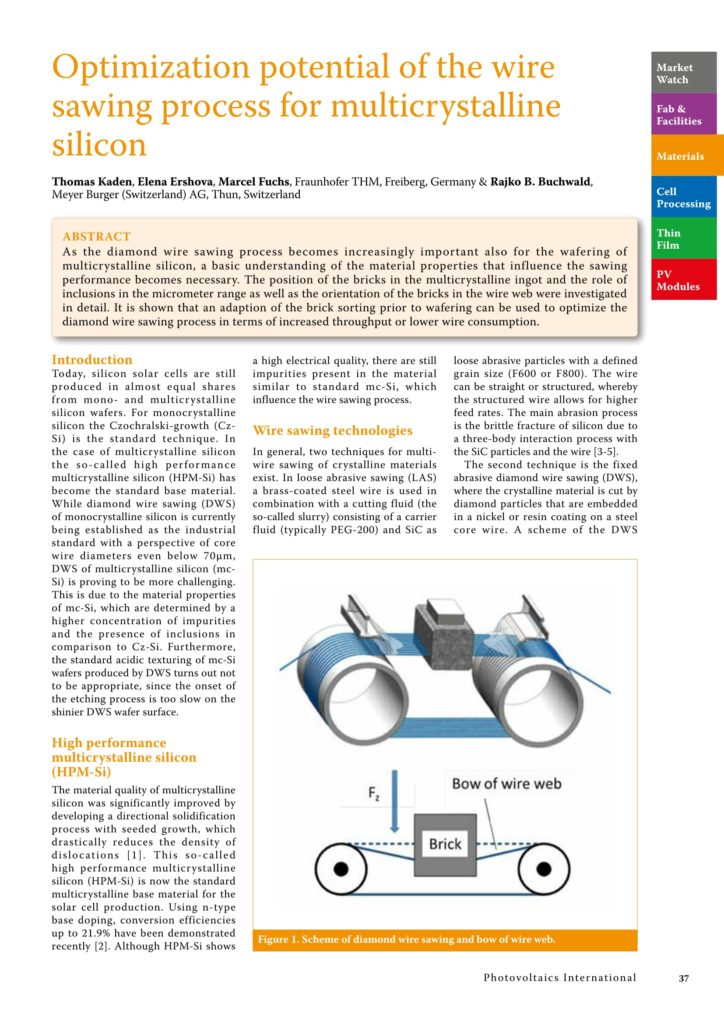

Today, silicon solar cells are still produced in almost equal shares from mono- and multi-crystalline silicon wafers. The authors here look at the scope for efficiencies in the wire sawing process for multi-crystalline silicon.