By Richard Russell, Loic Tous, Emanuele Cornagliotti, Angel Uruena de Castro, Filip Duerinckx & Jozef Szlufcik, Imec, Kaneka Belgium N.V.

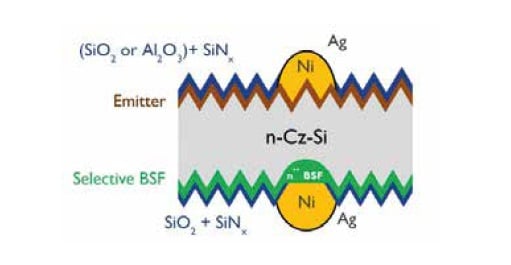

For many applications, bifacial modules offer a cost-effective way of increasing energy yields, which explains why the interest in bifacial cells in the PV industry is steadily growing and is expected to continue. However, the metallization of bifacial cells creates new challenges, as the same materials and techniques developed for n surfaces are generally not directly, or simultaneously, applicable to p surfaces; this necessitates sequential metallization of each side, resulting in added cost and/or complexity. This paper introduces a simple co-plating approach with the objective of simplifying the metallization of bifacial cells in a cost-effective way, and which is designed for multi-wire module integration. The metallization route is described, and high cell efficiencies of up to 22.4% are demonstrated using this co-plating approach with bifacial nPERT+ cells (where ‘+’ signifies the bifacial nature of these cells). Initial thermal-cycling reliability data of test structures and 1-cell laminates is presented. Finally, cost-of-ownership (COO) estimates are given, which predict the co-plating approach to be ~40% cheaper than bifacial screen-printed metallization. It is shown that the combination of the high efficiency potential of nPERT+ cells and the reduced costs of co-plating has the potential to deliver module-level costs of ~$0.25/Wpe (glass–glass configuration).