By Haidan Gong, Wuxi Suntech Power Co., Ltd., Wuxi, China; Guofeng Wang, Wuxi Suntech Power Co., Ltd., Wuxi, China

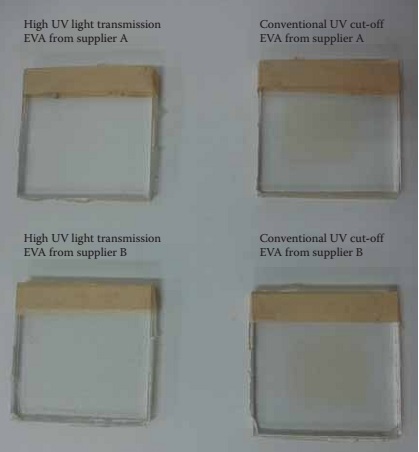

Newly developed high UV light transmission ethylene vinyl acetate (EVA) has recently been extensively introduced for use in PV modules. It has been proved that this type of EVA can result in potential power gain because of the better blue light response of the solar cell, which in turn can further reduce the cost per watt of the PV module. However, if only high UV transmission EVA is used as an encapsulant, too much UV light irradiates the backsheet, which can cause the backsheet to yellow. In order to improve the reliability and durability of the modules, SUNTECH, as a module manufacturer, therefore uses combined EVA, i.e. high UV transmission EVA as the front encapsulant and conventional UV cut-off EVA as the rear encapsulant, to protect the UV-sensitive backsheet. This paper presents the results of an investigation of the reliability and durability of high UV transmission EVA in PV modules, through an enhanced UV test which exceeds IEC standards.