By Mohan K. Bhan, Vice President of Engineering, Moser Baer PV Technologies India Limited; Rahul Kapil, Moser Baer PV Technologies India Limited; Indu Shekhar Bajpai, Moser Baer PV Technologies India Limited; Rajesh Kumar, Moser Baer PV Technologies India Limited; Vineet Jain, General Manager of Operations, Moser Baer PV Technologies India Limited; Sudheer Kumar, General Manager of the PV Solutions Group, Moser Baer PV Technologies India Limited

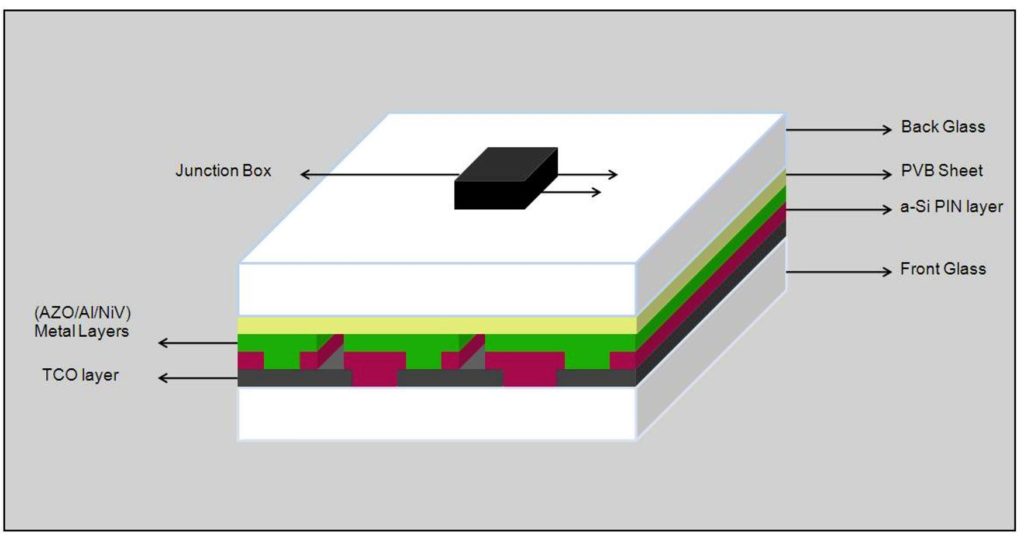

The recent photovoltaic industry shakeout which started around Q3 2008 has faced the overcapacity, credit crunch, and economic crisis that significantly declined the average selling price by 50 - 65%, including the price of thin-film photovoltaic modules. The changing business environment has put significant pressure on all PV manufacturing technologies but more candidly on amorphous silicon thin-film single-junction module manufacturers to advance and scale up the device efficiency and aggressively drive cost reduction. This paper outlines the approach taken at Moser Baer Photovoltaic Technologies India Limited (PVTIL), including process optimization and device management strategies, to enhance the module efficiency (total area) of the single-junction amorphous silicon quarter size, 1.43m2, substrate as manufactured using Applied Materials’ SunFab line.