By Sascha Dietrich, Module Reliability Group, Fraunhofer Center for Silicon Photovoltaics CSP; Matthias Pander, Module Reliability Group, Fraunhofer Center for Silicon Photovoltaics CSP; Martin Sander, Module Reliability Group, Fraunhofer Center for Silicon Photovoltaics CSP; Rico Meier, Module Reliability Group, Fraunhofer Center for Silicon Photovoltaics CSP; Matthias Ebert, Head of the Module Reliability Group, Fraunhofer Center for Silicon Photovoltaics CSP

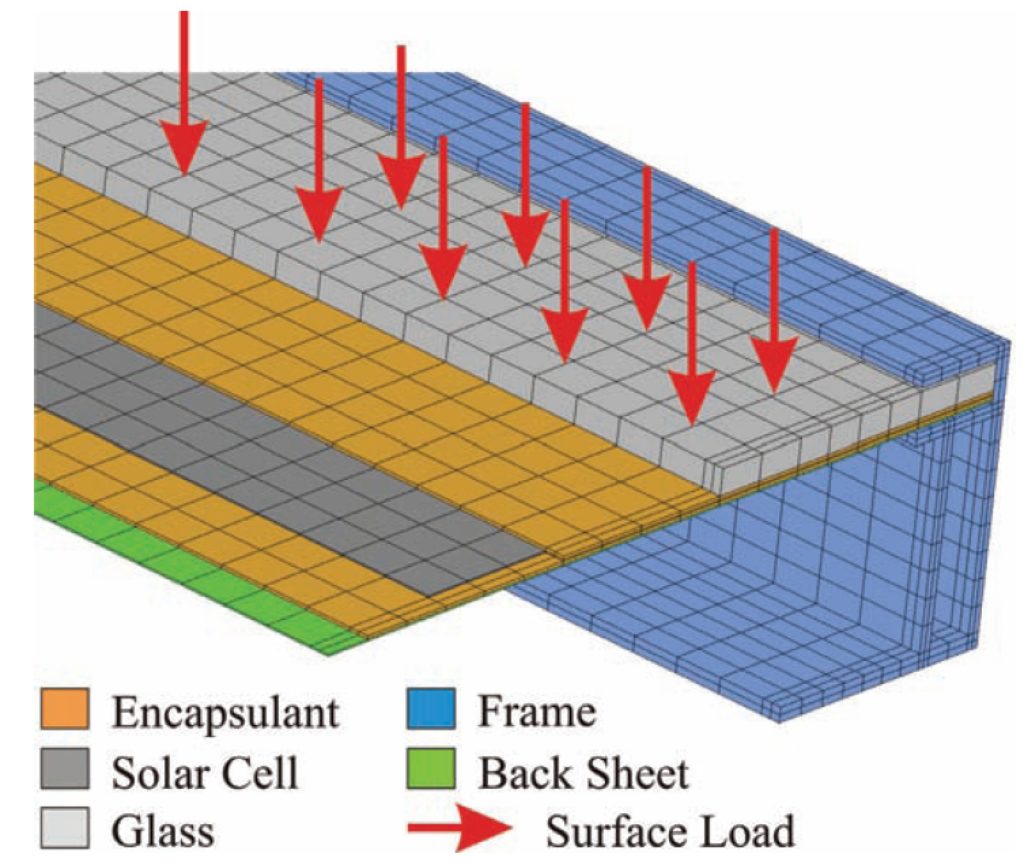

Cracking of solar cells is a serious issue for product safety and module performance. Cracks may result in power loss, hot spots or arcing, and are caused by exceeding the strength limit of silicon. During the last few years, various studies have shown that fracture of encapsulated solar cells can be influenced by the manufacturing processes, which lead to residual stresses in solar cells. The results presented in this paper will give insights into the stresses generated by soldering and lamination. Furthermore, mechanisms of stress generation will be explained. On the basis of these findings, recommendations are made as to how to mitigate stresses, for example by means of alternative soldering processes, different soldering parameters or material optimization of the copper ribbon or the encapsulant.