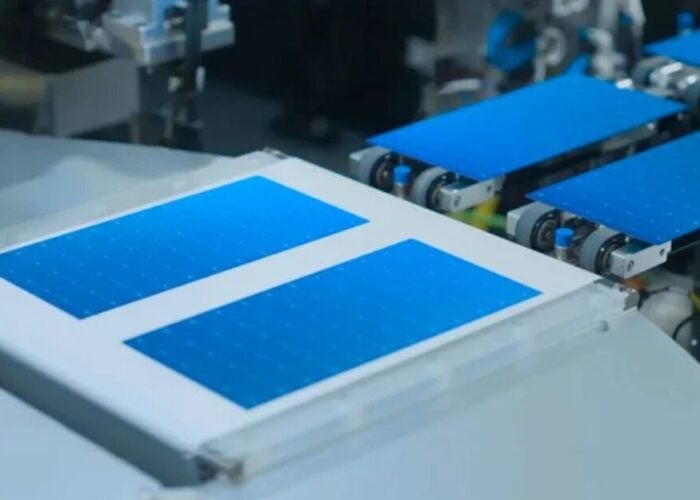

The Centre for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) and technology partner, Manz have achieved a small area CIGS cell conversion efficiency of 21%, verified by Fraunhofer ISE.

ZSW noted that the new CIGS cell architecture incorporated intermediate films (buffer layer) of zinc oxysulfide (front contact) and zinc magnesium oxide, deposited in a chemical bath, instead of cadmium sulfide and zinc oxide buffer layers.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

As a result, ZSW achieved a record cadmium-free solar cell with a surface area of 0.5 square centimetres.

“First and foremost, the buffer layer transmits more light without the cadmium sulphide,” said Prof. Michael Powalla, ZSW board member and head of the photovoltaics division. “In theory, we could use it to achieve even higher efficiency than with previous CIGS cells. The alternative buffer layer and the cadmium sulfide buffer are both deposited in a chemical bath, so a transition to manufacturing is possible without requiring additional processes.”

The improved cell front contact of zinc magnesium oxide replaced a thin zinc oxide film, while the buffer layer of zinc oxide-sulfide was found to be more transparent to light in the blue wavelength range.

ZSW expects that commercial CIGS thin-film modules made by Manz could be brought to market within a few years.