Business transactions are very often about relationships — the solar industry is no exception. But have plunging prices of PV thrust upon the nascent global market by the Chinese really spoilt the industry with too much choice? Has the young bachelor industry been too busy speed dating with $0.65/Wp panels at the expense of a stable and more meaningful relationship between investor, developer and consumer expectations of a quality product that is going to stand the test of time?

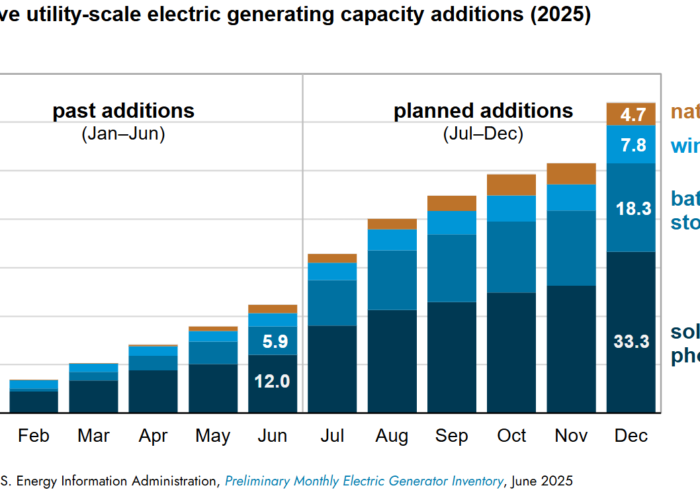

Many of the estimated 3.2GW of solar PV systems being installed in the US this year are sure to outlive many a marriage.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Power Purchase Agreements of 20 or 25 years have cemented solar's reputation as a dependable source of future electricity; the clean-living energy resource you can take home to your parents.

The frivolous analogy is my own. But many in the industry are seriously concerned that pressure to produce at the lowest (often loss-making) cost is possibly having an impact on module quality and therefore increasing risk for investors and developers. As the downstream part of the industry is the most promising segment for US solar, news of declining quality is unwelcome for those into one-night stands or a timely warning for those looking for something more steady.

Bankability has long been a popular buzzword in solar finance. Jennifer Granata of Sandia National Laboratories in New Mexico recently re-defined bankability as “investment worthiness” at Solar Power International last month.

Component reliability, production forecasts, project design, and credit-worthy customers, all play their part, she said.

As co-founder and CFO of SolSystems in Washington, DC, George Ashton is a matchmaker — of sorts — between investors and developers.

SolSystems was established in 2008 to create a stable cash flow through long-term fixed contracts in the market for solar renewable energy certificates (SRECs), which at the time were only traded on the spot market, he said.

“We all know that SRECs can be a difficult part of project finance on the east coast so we were able to purchase the rights of the SRECs up front and take the risk off the table for the developers and investors, obviously at a discount.”

SolSystems claims now to be the largest SREC aggregator and only one of two funds that pays upfront for SREC rights. It now has 350 developer and installer partners with a portfolio of more than 30MW and has facilitated US$150 million in project financing through SRECs.

SolSystems' SREC strategy for matching the right investors with the most compatible developers was so successful that late in 2008, the company expanded to the “entire deck of debt and equity financing” such as tax equity, said Ashton.

“We're bringing an investment banking structure to the industry and marrying developers with projects that are sophisticated and a little bit complex with the investors that are best suited to take on those risks and pay the most for those projects.”

SolMarket is the company's project development and finance arm for 220 solar projects with US$2.63 billion in aggregate capital seeking projects across a network of 300 members and 25MW of projects financed or at term sheet.

“We thought it was important especially in commercial solar to create an environment where investors and developers could interact without worrying about counterparty risk and whether or not the facts they were seeing were true. There was a lot of wasted energy in transactional space in commercial solar.”

Often good projects would go unfinanced if they were too small. But he said increasing standardization of the asset class could expand the pool of “good” projects that would attract investors.

“That's not to say that every project is going to look the same because it's not,” he said. “But [standardization] will help investors more quickly identify risks and mitigate those risks.”

By the time the bespoke due diligence process is complete, much of the capital is spent on a project, he said.

So much for a good marriage between developers and investors. But what about technology?

Matthew Frankel of Rabobank’s subsidiary, De Lage Landen Financial Services, said: “With so many manufacturers going out of business — product bankability has become a growing concern.”

De Lage Landen favours partnerships with “investment grade or near investment grade” manufacturers.

“It's no secret that that has been a challenge and we're seeing it all over the press today that manufacturers who we thought would be long-term players or not and those who are regarded as making quality products it's becoming more of a question — what kind of product are they ultimately shipping to their customers.”

Pascal Storck is a renewable resource analyst with 3TIER in Seattle. He has challenged solar developers to avoid the same mistakes made in the wind industry with sloppy data.

“Modelling companies were out selling data and overstating the accuracy of their products and not providing a realistic view of the uncertainty. It didn't work in the wind space, it led to a lot of under-performing projects. Let's not do the same thing in the solar space. Let's not have selection bias, where there is an over abundance of enthusiasm and too little empirical evidence to the risks.”

Storck said that over-reliance on satellite data was a risk too far as estimates of solar irradiance have a fairly large range of uncertainty.

“We understand hardly anything about the impact of aerosols around the world. A lot more R&D needs to be done. That's why site specific measurements give us that local flavour of context — how transparent is the atmosphere?”

Ground observations matched with satellite data and context was the most effective way to reduce uncertainty — a risk mitigation strategy that would become ever more important as federal incentives ramp down towards 2016.

“Projects have been financed based purely on satellite data alone, sometimes from very coarse resolution satellite data, no ground observations whatsoever, and no track record of the engineering procurement and construction company, or even solar panel manufacturers.

“Simply because the incentives were so high to develop those technologies and the loan guarantees were so rock solid that they could proceed. By definition if the risk is hedged, it's a bankable project.”

Just as happy hours in solar have turned into miserable days of lingering hangovers and catastrophic quarterly results.

But some in the industry are beginning to wake up and reach for the Alka Seltzer.

Pressure to produce ever cheaper panels is already impacting quality and increasing risks of degradation, said Ian Gregory, of SolarBuyer in Marlborough, Massachusetts.

SolarBuyer has independently audited 40 mainstream module manufacturers.

“We found that most of the engineering audits are paid by the manufacturer,” said Gregory. “That has to question the objectivity and independence of the results. We've certainly seen some discrepancies between results of an independent audit and the results of an audit paid for by the manufacturer.”

Interestingly, the Tier 1 status of a manufacturer was no guarantee of quality, according to SolarBuyer's results.

“We found that the assumption that Tier 1 manufacturers always deliver a good quality, good performing and reliable module is not true. Likewise, as you go [down] through the tiers, it's not always true that quality declines.

“This for us was a very important tool to help us in guiding investors and banks and developers as to which modules are really the best fit for the project.”

SolarBuyer had inspected more than 100,000 modules pre-shipment from a variety of manufacturers to identify the potential performance or reliability risks.

Gregory said the results were “astounding” and included unsoldered cells, heavily bowed cells, micro-cracks in cells, poor lamination, poor frame sealing and suspect flash testing.

“Between Q3 2011 and Q2 2012 we've seen an average latent defect rate [increase] of around 8%. These are the kinds of defects that are going to hit in the 5 to 10 year timeframe and combined with the factory auditing work we've done, we've seen clear indications that the significant cost pressure that many manufacturers are under is resulting in lower quality product being shipped into the marketplace today.

In Europe, “catastrophic system failures” have led to increasing numbers of manufacturers that Munich RE will not insure and Deutsche Bank will fund a maximum of 60% of a system's total cost to protect themselves, he said.

“Often [the] risks of [defects] are not transparent. Buyers and investors need to be doing more to protect themselves against some potentially significant risks to investment.”