Bifacial solar technology was first developed back in the 1960s. Initially considered too costly, over some decades it remained dormant while the overall PV market boomed. However, with bifacial cells now becoming more or less a commodity within various cell technologies, the sleeping beauty of bifacial PV has finally awakened.

To accompany the rapid uptake of bifacial installations it is essential to provide practical guidelines for their configuration to optimise LCOE. Compared to monofacial installations the bifacial configuration concerns more parameters with complex interrelations and different geographical response.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

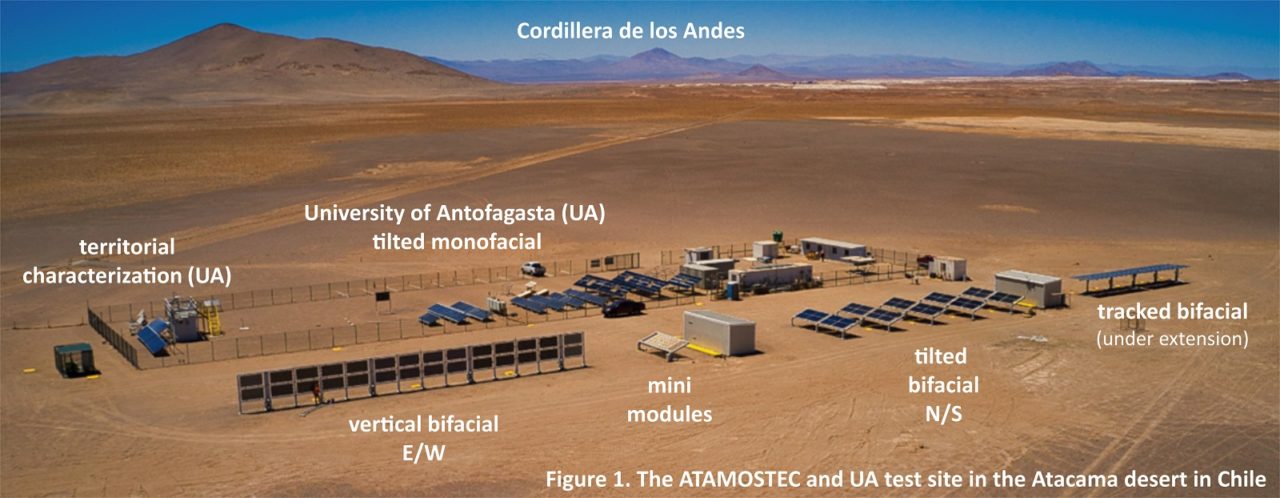

The ultimate goal of modelling is to turn the complexity of so many system parameters and with varying constraints into a manageable simplicity, offering reliable and simplifying solutions using straightforward input. This article summarises how the rapid progress made over recent years has improved understanding of design rules for bifacial PV. It also examines some case studies from within the ATAMOSTEC consortium operating in the Atacama Desert in Chile, as a collaborative effort between several institutional and industrial partners.

With the improved understanding of bifacial yield and the resulting best practices, bifacial PV shows strong signs of bloom in emerging markets such as Latin America, where companies such as Enel Green Power are turning to bifacial PV in order to power large-scale (200-600MW) solar projects in Chile, Brazil and Mexico. In addition, due to the recent exemption of bifacial panels from Section 201 import tariffs, US bifacial installations are expected to reach 2GW in 2020. [1]

Five rules of thumb for bifacial installation design as found by modelling and as discussed in this article

- 2D models give correct relative trends but underestimate absolute rear irradiance

- The impact of the mounting structure cannot be neglected for bifacial losses diagnoses, forecast and yield.

- The optimal tilt angle for bifacial systems is larger than for monofacial systems. This difference increases with ground albedo and latitude.

- For vertical bifacial configurations, the bifaciality of the module (back-to-front ratio) strongly affects the energy yield and the LCOE of the system. This effect is independent of ground reflectivity.

- The gain obtained by tracking is additive to the bifacial gain of a fixed-tilt system

Looking back: bifacial manufacturing, measurement and modelling

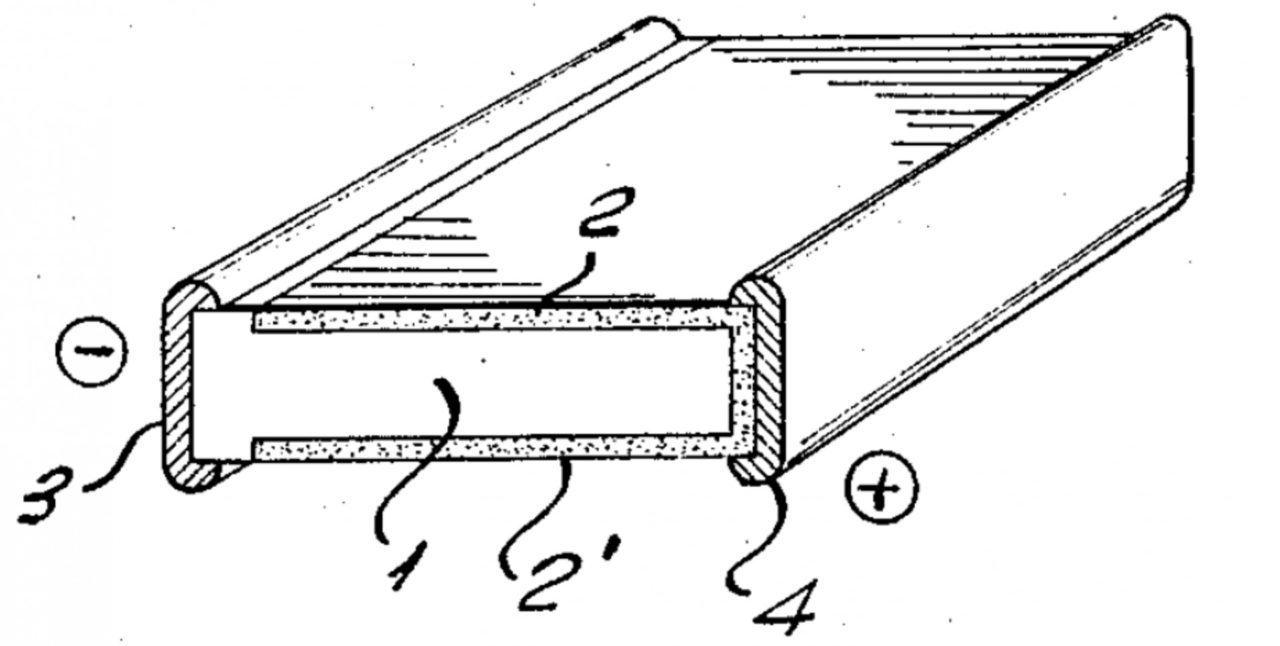

While the first bifacial cell patent was granted in 1960 and bifacial solar technology further developed in the late 1960s, it took surprisingly long – until the early 1980s – before the simple yet effective energy gain of the module backside was even considered for effective exploitation by collecting the ground albedo. Researchers at UPM Madrid reported bifacial energy gains of 35% in summer and over 50% in winter by using white painted walls and ground surfaces. [2] In 1986, the same group at UPM Madrid came up with a bifacial model based on a View-Factor approach that again estimated very high bifacial gains of up to 60% in winter. [3] Much more modest gains of around 20-25% were reported in 1993 by Martin Green at UNSW Sydney. [4]

The earliest appearance of bifacial PV in real-world applications, although somewhat out of this world, happened in Russian spacecrafts in the 1970s [5] and later on in the International Space Station, launched in 2000, where bifaciality offered increased sunlight collection from the Earth's albedo, which could avoid sun-tracking as required for monofacial modules. On the space station the module backside was found to produce about one third of the power of the module frontside. This in-orbit performance validated the results of a bifacial performance model that had been developed by NASA [6].

Whereas bifacial modules were deployed at the ISS because their doubled-sided light capture allowed the system to avoid sun tracking, recent years have seen a growing awareness of the benefits of using tracking on ground based bifacial systems. ENEL Green Power is operating such an innovative bifacial plant with horizontal single-axis tracking (HSAT) [7] at the site of La Silla in Northern Chile. Tracking of the modules and the resulting increase of tilt angles appears effective in reducing the effect of soiling in sandy climates like a desert [8,9]. Some modelling results on the La Silla plant will be discussed in the section on case studies.

This is an extract of an article first published in Volume 24 of PV Tech Power. The full article can be read here, or in the full digital copy of PV Tech Power 24, which can be downloaded via the PV Tech Store here

Acknowledgements

The work described here is part of the ATAMOSTEC. We recognise the support provided by the Chilean Economic Development Agency (CORFO) with contract No 17PTECES-75830 (AtaMoS TeC). Special thanks to Hervé Colin for managing the outdoor monitoring site at CEA-INES.

References

[1] Wood Mackenzie Power and Renewables, “Global bifacial module market report 2019”, cited in https://analysis.newenergyupdate.com/pv-insider/first-solar-exit-epc-market-us-bifacial-installs-hike-four-fold-2020

[2] A. Cuevas et al., “50% more output power from an albedo-collecting flat panel using bifacial solar cells”, Solar Energy, Vol.l9, pp.419-420, (1982).

[3] A.Krenzinger et al., Estimation of Radiation Incident on Bifacial Albedo-Collecting Panels, International Journal of Solar Energy, Vol.4 (5), 1986

[4] M.Green et al., Computer simulation of enhanced output from bifacial photovoltaic modules, Progress in Photovoltaics, Vol.1, 293-299 (1993)

[5] G.A. Baltyanskii, N.M. Bordina, et al. “Test of experimental bifacial solar array on spacecraft Salut-5”, Cosmic Research 18, 812-814 (1980)

[6] A. Delleur et al., “Electrical Performance from Bifacial Illumination International Space Station Photovoltaic Array”, J. of Spacecraft and rockets Vol.42 (1), Jan.–Feb.2005

[7] A. Di Stefano et al., “La Silla PV plant as a utility-scale side-by-side test for innovative modules technologies”. In Proc. 33th EUPVSEC 1978–1982 (2017).

[8] E. Grau Luque et al., “Effect of soiling in bifacial PV modules and cleaning schedule optimization, Energy Conversion and Management”, Vol.174, October 2018, Pages 615-625

[9] M. Garcia et al., “Soiling and other optical losses in solar‐tracking PV plants in Navarra”, Progress in Photovoltaics, Vo.19 (2), March 2011, pages 211-217

Authors

Florent Haffner studied general engineering at Ecole Centrale de Lyon (France), with a focus on the challenges of energy transition. After various internships on renewable energies, he joined CEA-INES in 2018, working on bifacial modelling and PV integration into the electric grid.

Djaber Berrian earned his BSc in physics in 2013 at the University of Science and Technology Houari Boumediene in Algeria, where he also received his MSc in renewable energy in 2015 with a thesis on mathematical modelling for defective photovoltaic generators. Throughout his study he participated in different activities in the field of renewable energy. His passion for renewable energy brought him to ISC Konstanz in February 2017, where he is working as a PhD candidate on energy yield modelling of PV systems using the MoBiDiG software tool. He is also involved in the European project BiFaLo that has a focus on bifacial modules.

Francisco Araya Rojas studied electronic engineering at Universidad de Antofagasta where he received the MSc degree after he joined the Centro de Desarrollo Energético de la Universidad de Antofagasta (CDEA). He worked as a research engineer with focus on PV system performance. He is currently working on modelling of bifacial PV systems at CEA-INES toward a PhD degree in electrical engineering.

Elías Urrejola Davanzo is CTO of ATAMOSTEC and has worked in the entire PV value chain, from the production of industrial solar cells, design of pilot plants, testing of disruptive technologies in the desert and development of large-scale plants. He has been senior solar researcher and head of the bifacial PV project at Engie Laborelec Chile, director of the solar line and senior researcher at Fraunhofer Chile, specialist engineer at Air Liquide (France) and at Sunways AG (Germany) and researcher at ISC-Konstanz (Germany). He holds a PhD in physics from the University of Konstanz (Germany) and a civil electrical engineering degree from the University of Santiago, Chile.

Delfina Muñoz graduated as industrial engineer and obtained a PhD in photovoltaics from the Universitat Politècnica de Catalunya in Barcelona (Spain). She joined CEA-INES in France in 2008 as a postdoctoral researcher, where she became head of the heterojunction solar cells lab in 2010. She is a member of the steering committee of the nPV and tandemPV workshops and combines project work with laboratory activities, directing PhD students and developing next-generation heterojunction solar cells based on tandem technology.

Joris Libal is R&D project manager at ISC Konstanz, overseeing technology transfer and cost calculations in the areas of high-efficiency n-type solar cells and innovative module technology as well as energy yield simulations. He received a degree in physics from the University of Tübingen and a PhD in the field of n-type crystalline silicon solar cells from the University of Konstanz. He has been involved in the entire value chain of crystalline silicon PV, with various positions at the Universities of Konstanz and Milano-Bicocca and, prior to joining ISC Konstanz in 2012, as R&D manager at the Italian PV module manufacturer Silfab SpA.

Eric Gerritsen studied engineering physics at Twente University (The Netherlands) before joining Philips Research Laboratories (Eindhoven, NL) in 1985 to work on ion implantation, for which he received his PhD from Groningen University in 1990. He then held various positions within Philips Lighting and Philips Semiconductors in Germany, Netherlands and France. In 2008 he joined CEA-INES where he has been active on development and technology brokering of PV module materials, processes, equipment and applications.