The PERC (Passivated Emitter Rear Cell) cell and module technology have been widely adopted by the industry. JA Solar has been exploring innovative approaches of bifacial PERC cell and the methods of making it and has been granted two Chinese patents. Also, a series of experiments have been carried out to certify the higher efficiency of bifacial PERC modules than conventional PERC modules.

The implementation of PERC with Al2O3/SiNx dielectric passivation stack and localized contacts on the backside of main-stream p-type Si solar cells has become the prevailing technological approach to achieve high energy conversion efficiency for Si-wafer based solar cells in the PV industry for the past few years since JA Solar broke the 20% conversion-efficiency barrier for p-type mono-Si cells using screen-printing metallization process in the middle of 2013 and started mass production of PERC cells and modules at the beginning of 2014.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The large-scale adoption of PERC cell and module technology by the industry is primarily due to the fact that this approach is compatible with the screen-printing based manufacturing platform. This is because it only requires moderate retrofitting to the existing cell production lines, especially when the concerns over the costs of manufacturing wafer-based Si cells needs to be addressed. It is also fueled by the rapid progress in the development of high-throughput Al2O3 deposition equipment for PV application as the tools become more adaptive and affordable for the industry.

JA Solar has since taken the PERC cell technology one step further by utilizing the unique PERC architecture to structure it into a device capable of actively admitting light from its front (sunny) side and back (shade) side in a bifacial configuration.

This innovative approach of bifacial PERC cell and the methods of making it were granted by the National Bureau of Patents and Trade Marks of China as Chinese Patent CN103489934B in March 2016 entitled “Double-side Light Admitting Solar Cell with Localized Aluminum Back-surface Field and Methods of Making It”.

It further enriches JA Solar’s IP over Si-wafer based solar PV cells and modules with the Chinese Patent CN101853899B, covering laser processing and screen printing of PERC cells entitled “A Solar Cell with Localized Back-surface Field and Method of Making It”.

This innovation has led to the PV products from JA Solar being commercially available to the global market and recently expanded to include advanced double-glass modules assembled with high-performance bifacial PERC cells in both 60-cell and 72-cell formats. The volume shipment of such double-glass bifacial PERC (Bi-PERC) modules has started since the first half of 2017.

Generally, a bifacial module produces more energy than a mono-facial module with the same power rating under the same conditions. The amount of additional energy generation of a bifacial module, however, depends on specific conditions including the intensity of diffused light available to the backside of the bifacial module, albedo reflectance of the surface underneath the module, as well as the installation height of the module at the installation locations.

Field data collected from JA Solar’s double-glass bifacial PERC modules at various locations where a number of Bi-PERC modules deployed along with the same amount of regular PERC modules with front cover glass and conventional insulating white back sheet for comparative study, have shown that Bi-PERC modules consistently out-perform regular PERC modules in terms of energy yield.

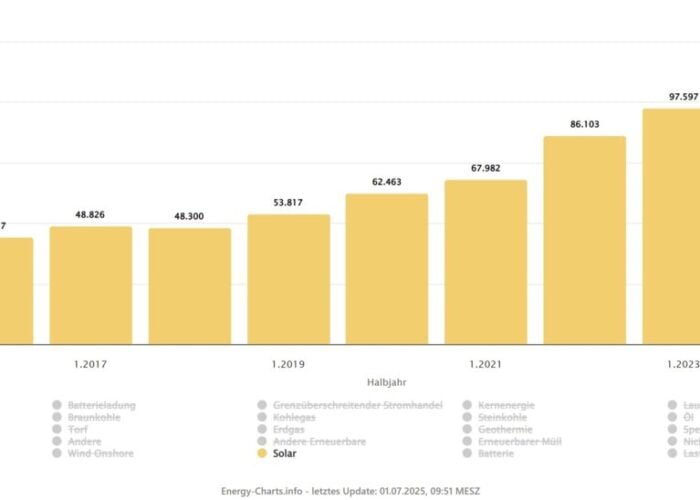

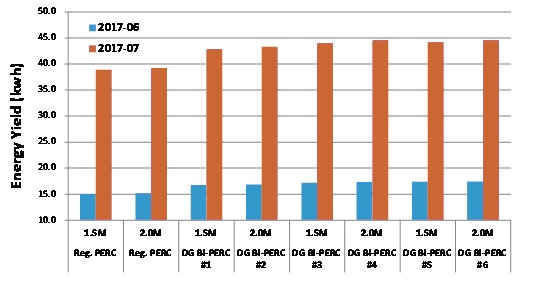

Shown in the chart below is energy generation data from a group of Bi-PERC modules and regular modules with mono-facial cells. The rated power is ~290W for the Bi-PERC modules (measured from the front side only with the back surface covered by a black sheet) and ~295W for the regular PERC modules. These modules are installed side-by-side on the same racking system with two horizontal rails in one of JA’s testing sites with two sub-groups at heights of 1.5 and 2.0 meters, respectively.

It can be clearly seen from the above chart that Bi-PERC modules yield additional energy in comparison with the energy generation by regular mono-facial PERC modules. The transparent back side of a Bi-PERC module allows the photons incident onto the active back surface of bifacial PERC cells to make an extra contribution to the energy produced by the bifacial PERC cells assembled in the modules.

It is also worth noting that the installation heights make a small difference in energy yield from all the modules as the higher the modules are installed, the better the performance of the modules. The difference observed at this particular location is about 0.5-1.5% relatively from 1.5 meters to two meters, most likely due to the intensity of available diffused light getting stronger as the module height is increased.

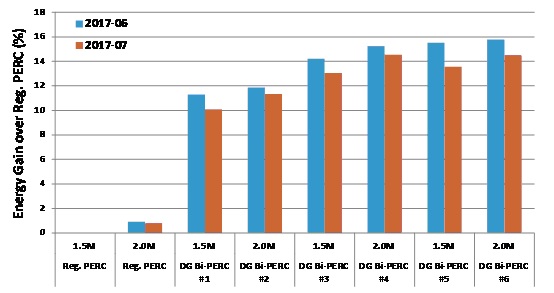

The ratio of the difference in the energy yields between Bi-PERC modules and regular PERC modules over the energy produced by the regular PERC modules is illustrated in the chart below.

There is approximately 8-15% additional energy (energy gain) yielded from the Bi-PERC modules as compared to that from regular mono-facial PERC modules. The variation of the energy gain from module to module for the Bi-PERC is a combined result of installation configurations and site conditions, as well as the encapsulation materials of the Bi-PERC modules.

It is also interesting to note that the ratio of energy yield from Bi-PERC over that of regular PERC is higher in the month of June than than in July accumulatively on a relative scale while the overall energy generation in June is much lower than that in July on an absolute scale.

This can be explained as the effect of weather conditions of the geographic region (City of Yangzhou in Jiangsu Province of China) where the modules are installed, as the regional weather patterns are for many rainy and heavily clouded days in June while much less such days occur in July. Since solar irradiance is consisted of both direct and diffused lights (for instance, 90% direct and 10% diffused in AM1.5G spectrum), a bifacial module has two active sides to admit the diffused light and therefore naturally works better than a mono-facial module having only one active side in terms of energy generation when direct light is scarcely available in a rainy or heavily clouded day, resulting in the higher energy yield ratio observed in June.

The bifaciality of JA Solar’s double-glass bifacial PERC modules, defined as the ratio of the output power measured from the backside of such a module over that measured from its front side, is currently at 70-75% in mass production.

It is primarily determined by the coverage of metallic contact grid mainly composed by Al paste on the total area of the back surface of the cells. It has to be pointed out that, while the bifaciality of a double-glass bifacial PERC module looks relatively smaller than that of a double-glass n-type bifacial module (~80-85%), Bi-PERC modules are still much more cost-effective in producing additional energy in terms of US$/W. This is because making Bi-PERC modules does not require any additional steps in the cell fabricating process at the cell level, so that there is no extra cost incurred except some fine tuning of process control.

While the cost of producing double-glass modules may remain the same regardless of the types of cells to be assembled with, making n-type bifacial modules needs several more major steps in its cell fabrication process as compared to that for p-type cells, inevitably resulting in some significant cost increase at the cell level. In addition, as the intensity of diffused and scattered light available to the back side of a string of tilt mounted modules is always about one order of magnitude weaker than that on the front side, a 10% discrepancy in bifaciality does not really make too much significant difference in yielding additional energy.

To date, JA Solar is actively working with a few selected metal paste suppliers to further refine the Al pastes for continuously improving the performance of bifacial PERC cells, which in turn, will further increase the listing power of Bi-PERC modules as well as the ability of yielding more additional energy from the backside of the modules.

JA Solar firmly believes that Bi-PERC modules are a cost-effective solution for yielding additional energy therefore reducing the leveraged cost of energy (LCOE) for PV systems large or small, as it has been proven by the energy generation data collected from the fields where the modules are deployed.

This blog illustrates the advantages of bifacial PERC modules. Experiments show that Bi-PERC modules yield additional energy in comparison with the energy generation by regular mono-facial PERC modules. JA Solar has been actively working on innovative use of PERC technology and double-glass bifacial PERC modules. Its patented bifacial modules have currently achieved bifaciality of 70-75% in mass production, which will contribute to lower LCOE.