Australian electrolyser manufacturer Hysata claims its electrolyser technology could enable hydrogen production costs to fall below US$1.5/kg by the mid-2020s.

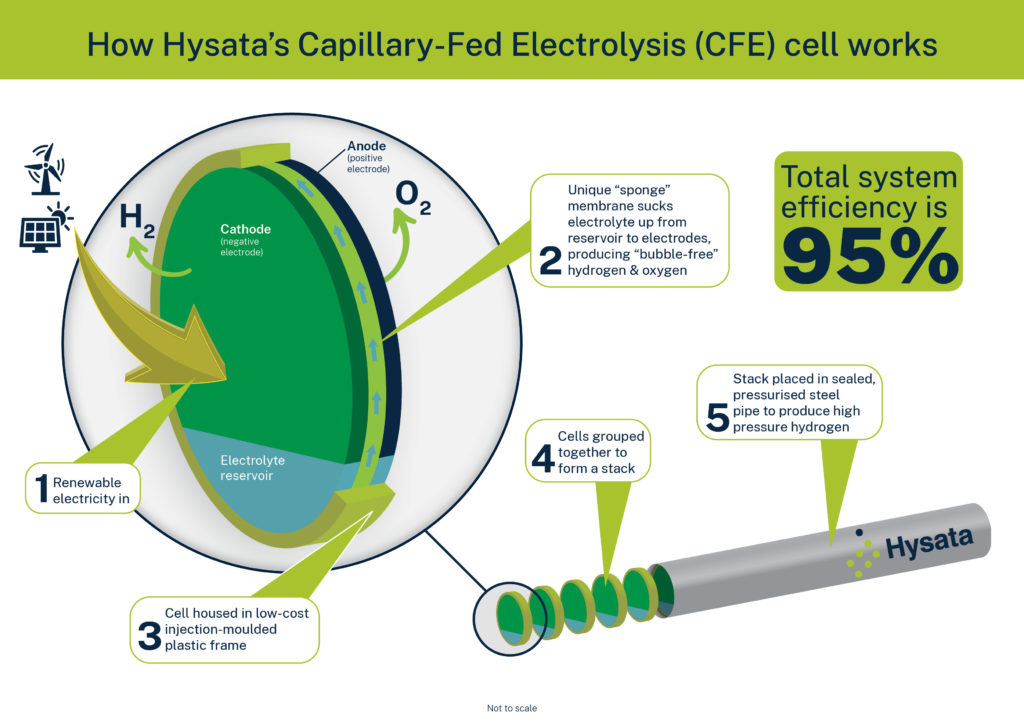

The research, which was published in the peer-reviewed scientific journal Nature Communications, confirmed Hysata’s ‘capillary-fed electrolysis cell’ can deliver a 95% system efficiency, almost 20% higher than modern alkaline electrolysers which produce the best system efficiency so far.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Paul Barrett, CEO of Hysata said the technology will allow green hydrogen to “outcompete fossil fuel-derived hydrogen” with production cost to fall below US$1.5/kg by the mid-2020s putting Australia as a “leading manufacturer” and exporter of electrolysers.

“This is critical to making green hydrogen commercially viable and decarbonising hard-to-abate sectors,” said Barrett.

Barrett’s prediction is five years earlier than IRENA’s or research firm IHS Markit’s prediction costs for green hydrogen being able to outcompete blue (or grey) hydrogen in all major markets, with IRENA predicting a cost of US$2.46/kg by 2030 for Australia using solar as the energy source.

Barrett added the company is on its way to commercialise the technology and reach gigawatt scale hydrogen production by 2025.

A report about hydrogen production costs from the UK government’s Department for Business, Energy & Industrial Strategy (BEIS), suggested conversion efficiencies would increase to 82-86% for alkaline, PEM and solid oxide electrolysers by 2050.

Gerry Swiegers, chief technology officer at Hysata, said: “Hysata’s overall electrolyser system has been designed for ease of manufacturing, scaling and installation, delivering 95 percent overall system efficiency, equivalent to 41.5 kWh/kg, compared to 75 percent or less for existing electrolyser technologies.”

Swiegers added the technology stands to reduce both capital and operational costs for hydrogen producers to make green hydrogen.

The technology was first created by scientists at the University of Wollongong and will be commercialised by Hysata, backed by IP Group and the Clean Energy Finance Corporation (CEFC).

With green hydrogen projects increasing in the past few years, many initiatives have been announced in the past two years to ramp up green hydrogen production.

During COP26 last year, the UN-supported Green Hydrogen Catapult (GHC) committed to bring 45GW of green hydrogen electrolyser capacity to a final investment decision by 2026 and commissioning by 2027.

An European initiative, the HyDeal Ambition initiative aims to achieve 67GW of electrolysis capacity by 2030 and deliver green hydrogen across Europe at €1.5/kg (US$1.82) before 2030.