‘Solar Module Super League’ (SMSL) member, GCL System Integration Technology (GCL-SI) is to build a 60GW solar module megacomplex in Hefei City, China at a cost of approximately US$2.5 billion over a four-year period.

The solar module megacomplex is the largest such project ever announced in the solar industry, according to PV Tech’s analysis.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

GCL-SI signed an investment cooperation agreement with the People's Government of Feidong County in Hefei City, Anhui Province, China with the megacomplex to be located in the Feidong County Circular Economy Demonstration Park, occupying the equivalent of 1.33km² to house all manufacturing operations and partner manufacturing and supply chain operations that would be necessary for such a large new manufacturing hub.

The megacomplex will include wafer, cell, module and all component manufacturing such as junction box, backsheets, glass, EVA and aluminium frames and work is to start in 2020.

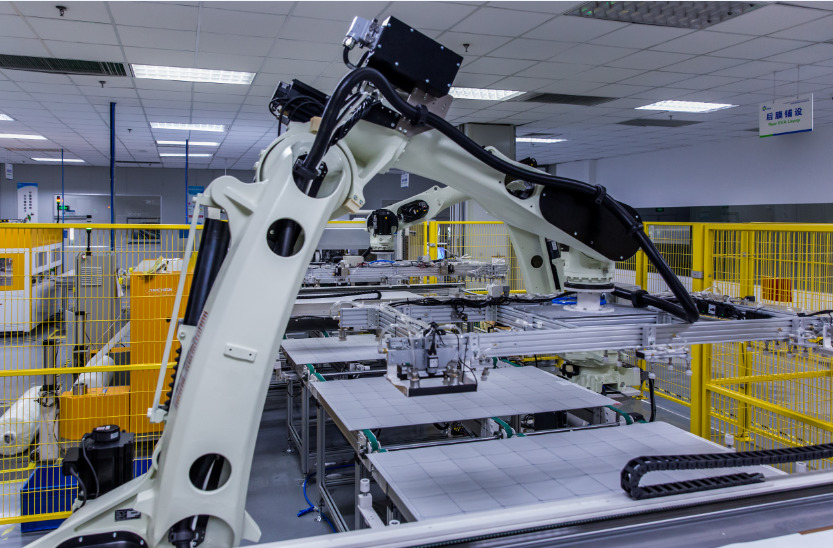

The four-year, four-phase implementation plan includes an annual investment of approximately RMB 5 billion (US$700 million) for 15GW of integrated PV module assembly capacity. The facilities would also be highly automated and include an array of advanced manufacturing technologies.

GCL-SI also noted that the majority of module manufacturing would be focused on using 210mm x 210mm large-area monocrystalline wafers.

A key aim of the megacomplex is to meet future demand and significantly drive down the manufacturing cost of PV modules to unprecedented levels.