PV equipment supplier RENA technologies has secured its largest ever single order from a major PV manufacturer in Asia as part of the customer's new 15GW PERC cell capacity expansion plans.

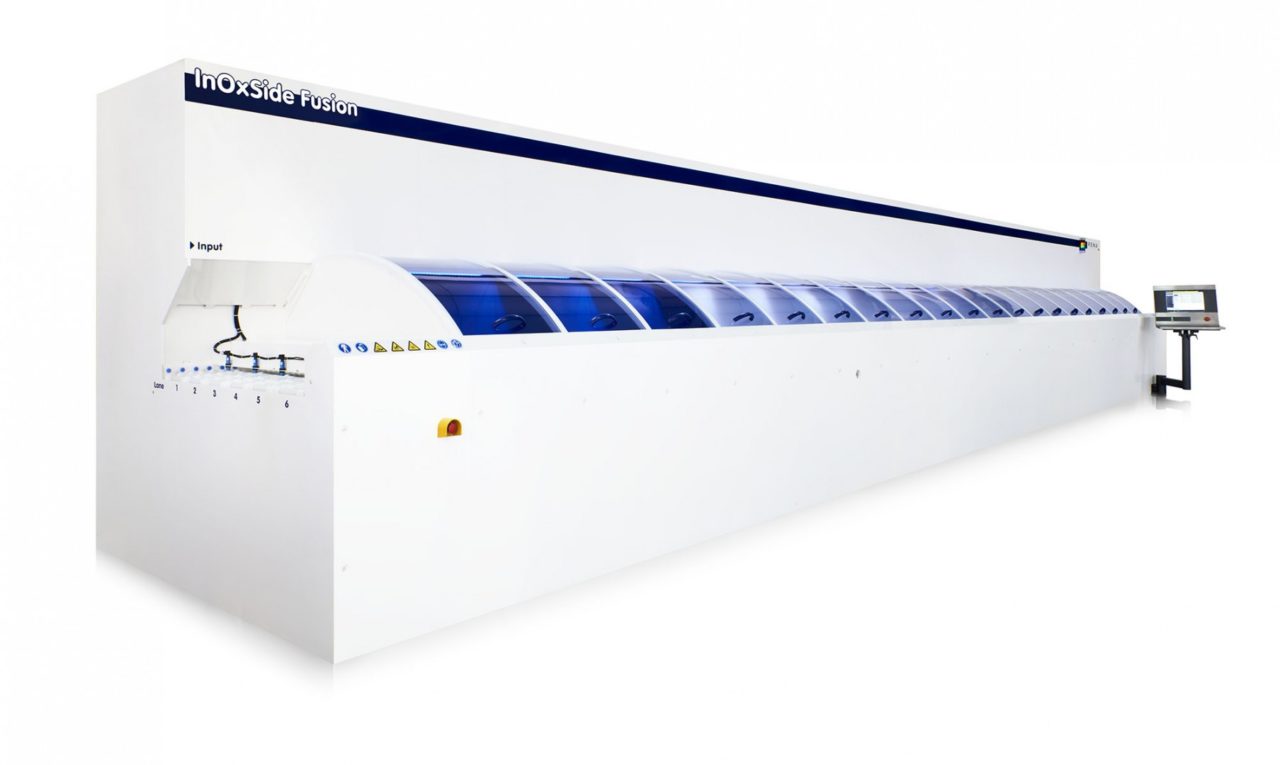

RENA said that the order was worth ‘tens of millions of euros’ and included its BatchTex XL and InOxSide Fusion wet chemical high-volume processing tools that will be used in several cell plants and enable a reduction in chemical consumption, lowering manufacturing costs.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

The newly developed InOxSide Fusion technology was said to have a very short acid process with an additional alkaline process step. This development makes it possible to use significantly less nitric acid, leading to a reduction in production costs, according to RENA.

Peter Schneidewind, CEO of RENA Technologies said, “We are implementing extremely innovative technology which has been developed by our teams in Germany and China in record time. We are delighted that the innovative strength of RENA and the reliability of our systems are valued by our customer.

The BatchTex XL machines ordered for solar wafers also lowered costs.

Ulrich Jäger, vice president of sales at RENA, added, “The comparatively space-saving solution offers our customer enormous potential savings and sets new standards in wet chemical processing technology. The trend towards M12 wafers continues to grow and thanks to our machines, we are extremely well prepared for it.”