NuVision Solar, a new US-based solar manufacturer, has been formed and aims to build a heterojunction (HJT) solar cell and module assembly plant in the US.

The manufacturing plant, which will have an annual nameplate capacity of 2.5GW, is targeted to begin module production in the fourth quarter of 2025. Modules produced at the plant will be directed towards the utility-scale, large-scale commercial and residential solar markets.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

However, the company has not yet disclosed in which state the plant will be built. PV Tech reached out to NuVision Solar regarding the location of the manufacturing plant. According to the company, the modules will meet the domestic content requirements and qualify for the additional 10% bonus part of the Inflation Reduction Act.

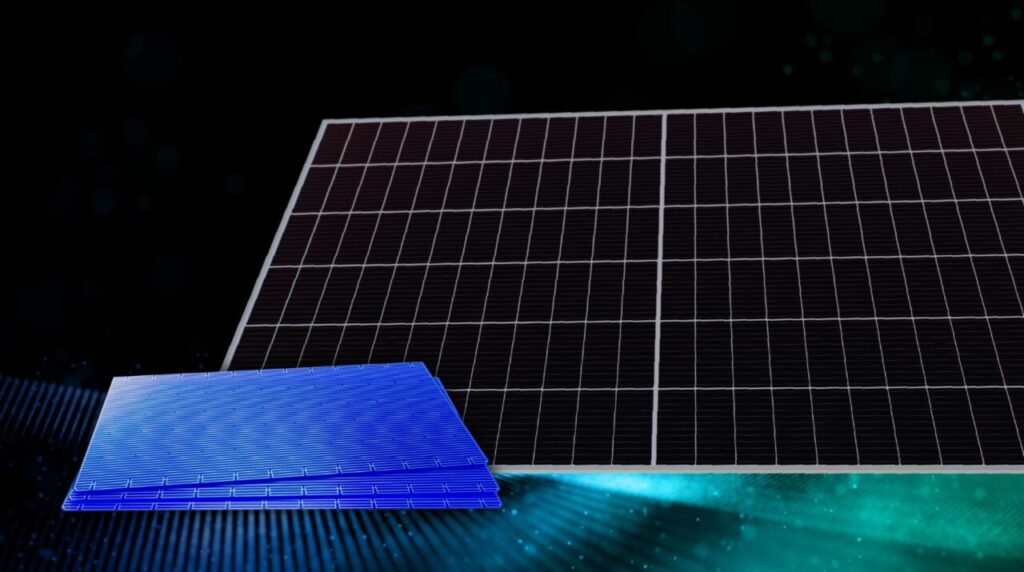

It will produce bifacial modules with a power output of up to 800W, with a 35-year performance warranty and a 20-year product warranty. NuVision Solar said the company is backed by an executive team with over two decades of solar cells and module manufacturing experience.

“Heterojunction technology enables us to achieve exceptional cell efficiencies and consistently high performance across a wide range of conditions,” said Dr Tom Mueller, CTO at NuVision Solar.

Most of the capacity currently being built in the US is for tunnel oxide passivated contact (TOPCon) technology, with a few companies, such as NuVision Solar, building HJT capacity. Among others are Swiss-owned PV manufacturer Meyer Burger, which abandoned its solar cell manufacturing plans earlier this year, and US-based solar manufacturer Solarix, with an annual nameplate capacity of 1.2GW for HJT modules in Virginia.

“By integrating these advanced cells into our modules, we are improving overall system performance, delivering more energy over the lifetime of the installation, and ultimately enhancing the value proposition for our customers,” added Mueller.