By adopting and modifying technology initially developed by NASA, SunSniffer is able to provide STC (Standard Test Conditions) values of each individual module, on a constant basis during pv power plant operation. This unique technology has been developed with the German Aerospace Center, which consists of software managing Big Data with artificial intelligence and high-precision measuring hardware. Results were presented on Fraunhofer CSP, PV Days in October 24, 2018.

Problem

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

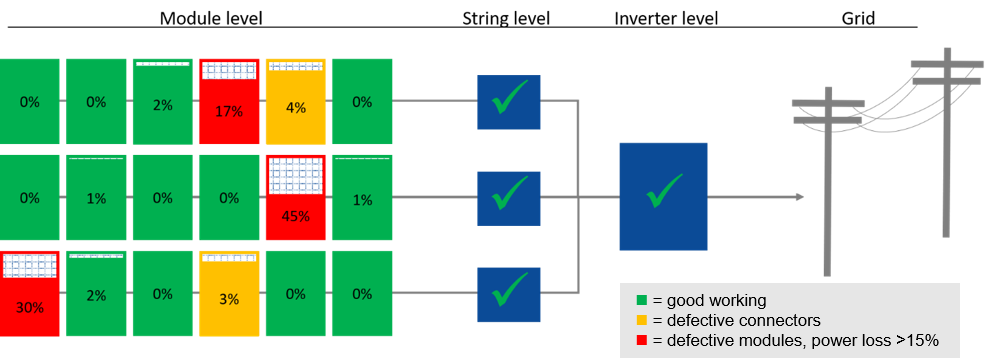

Typcially, the standard way to determine the performance of PV modules in the field is to make inspections of module arrays through thermal imaging IR (Infrared) to detect and locate the potential performance and degredation issues. Then a service in which the faulty modules are demounted, taken to a laboratory for further qualified testing, then potentially transported back to the plant to being re-installed. This is the most time consuming and expensive procedure, which can lead to plant operators skipping minor issues are skipped and only the biggest problems being taken care of. Therefore, the dilema is how to claim on module warranties as the manufacturers need indepedent proof of the issues impacting the performance, typically the accurate percentage of power reduction in the in the field, without demounting and lab-testing expenditures?

Solution

With its adapted NASA technology, that whole process can be reduced to the push of one button, according to SunSniffer. With a dataset collected for just one week of field operations, coupled with SunSniffer’s ‘virtual flasher‘ of the (Digital Twin technology) can provide the final exact STC values of each module within the dataset chosen. Shadings, soilings or defective modules are recognized beside STC values and classified. Cleaning, repair or exchange services can be coordinated depending on the respective cost efficiencies. This is made possible by an integrated sensor which costs less than 1 Cent per Wp. This works by deploying half-minute interval measurements from the sensors from each individual module, which is processed by artificial intelligence. The more data collected, the better the accuracy of final analysis.

Application

PV power plants of all sizes, unlimited scalability.

Platform

Condition-based plant analysis by SunSniffer Digital Twin is part of the SunSniffer PV plant analytics technology, which measures and analyzes PV plants of all sizes, providing the most-precise condition reports and clear solution proposals in case of failures. The system consists of mentioned software as well as of hardware: sensors in each module and a string measurement device. An integrated Gateway transmits all measured data including inverters and environmental sensors to the analyzing Webportal.

Availability

SunSniffer‘s Digital Twin technology will be released to its customers on December 1st. 2018.