North Carolina-based high-efficiency concentrated photovoltaics (CPV) manufacturer Semprius claims it has developed a new stacked solar cell that brings closer the promise of 50% conversion efficiency.

Its latest stacked four-junction, four-terminal solar cell using Sempius' micro transfer process can reach efficiencies of 43.9%, according to the company.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

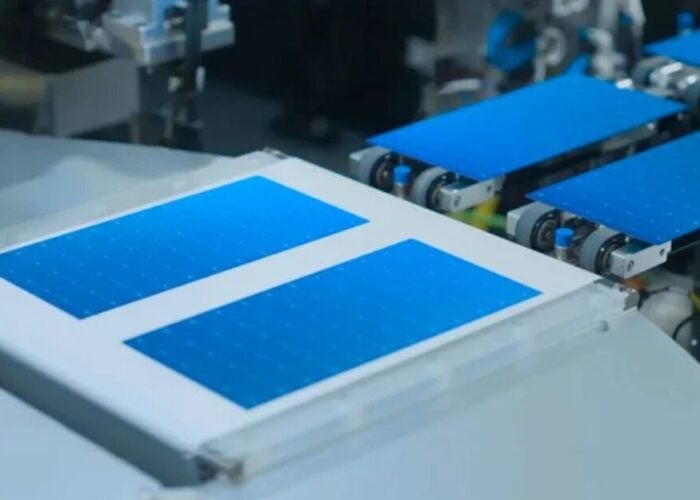

Using high-speed micro transfer, a three-junction microcell is stacked onto a single-junction germanium microcell, enabling thousands of stacked microcells with very high yields to be simultaneously formed.

Semprius claims that due to the four junctions created, the cell can tap light from across a broader portion of the solar spectrum and therefore achieve higher efficiencies than conventional silicon and thin-film single-junction solar cells. The company believes that the new cell provides a “near term pathway” to CPV solar cells of 50% efficiency.

Semprius attributes much of the improvement to a new interfacial material used between the top and bottom layers of the cell. The material minimises optical losses within the stack to optimise conversion efficiency. The four terminals also mean that the cell has reduced spectral dependence and increased yield under normal conditions.

The cell was developed by Semprius in collaboration with Frederick Seitz Materials Research Laboratory at the University of Illinois at Urbana-Champaign, led by Professor John Rogers as well as with commercial partner Solar Junction, which manufactures III-V high-efficiency solar cells. Results of the latest project will be published in the journal Nature Materials.

Semprius vice president of technology, Scott Burroughs, said that the process used to make the cell is fully compatible with the company’s production processes already in place, making it relatively easy to transfer the latest demonstration to a manufactured product. Semprius was previously a beneficiary of the Department of Energy’s Sunshot incubator programme.

Analysis firm IHS recently issued a report which claimed commercialised CPV cells will reach 45% efficiency by 2017, with the competitive market for CPV expected to “liven up”.