US-based solar manufacturer T1 Energy has expressed support for the US government’s tariff investigations into global polysilicon imports and solar products from Laos, Indonesia and India.

In the last month, the US Department of Commerce (DOC) has announced a probe into polysilicon imports to the US and a new antidumping and countervailing duty (AD/CVD) investigation into solar products from Chinese-backed firms in Laos and Indonesia and Indian firms shipping to the US.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

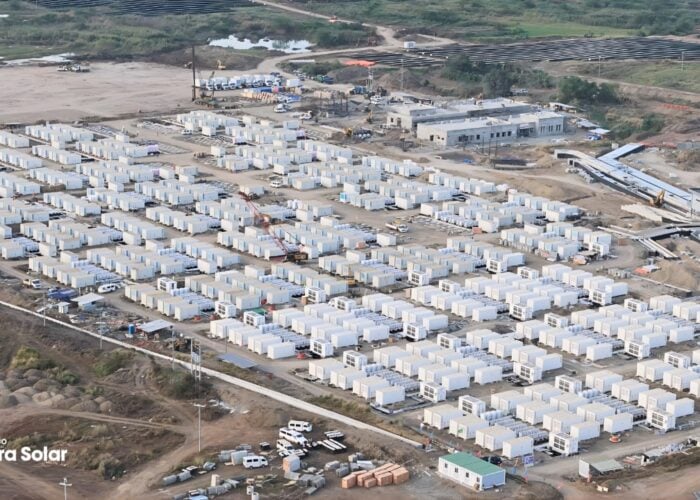

T1 Energy currently operates a module manufacturing facility near Dallas, Texas, and plans to produce solar cells at a planned 5GW facility outside Austin. The company was formed when Freyr Battery – as it was formerly known – bought the Dallas module facility from Chinese solar manufacturing giant TrinaSolar in December 2024.

Section 232

The company said it “supports” the DOC’s Section 232 investigation into polysilicon imports. The investigation reportedly seeks to determine the effects of polysilicon imports to the US, how they affect domestic production, and the role of foreign supply chains in meeting domestic demand.

In a public statement, T1 Energy said it believes the investigation “will result in strengthening US energy security and boosting American advanced manufacturing.”

It also said its “contract to purchase hyper-pure American polysilicon would likely be advantaged by any potential tariffs or import restrictions that result from this case.”

T1 Energy has not yet announced who it has signed polysilicon supply contract with, but in its most recent public financial filing it said: “We are sourcing polysilicon, the key raw material in solar equipment production, from the United States”.

AD/CVD

The company also said it planned to file in support of the new AD/CVD tariffs.

“T1 expects to benefit from potential tariffs under this case, which will support the Company’s efforts to build a vertically integrated supply chain including the G2_Austin solar cell manufacturing facility,” the company said.

The AD/CVD case was brought by a group representing a handful of US solar manufacturers, including First Solar, Hanwha Qcells and Mission Solar. As a cadmium telluride (CdTe) technology module producer, First Solar would be unaffected by tariffs on silicon imports, and both Qcells and Mission Solar have captive supply of polysilicon and other upstream components via their Korean owners, Hanwha Solutions and OCI Group. Other competitor manufacturers are likely more exposed to unpredictable tariff rates.

Daniel Barcelo, CEO of T1 Energy, said: “It is time to bring back American manufacturing. We’re doing that at T1 Energy. The Commerce Department’s 232 polysilicon investigation and the Solar 4 AD/CVD case should strengthen our efforts to build an American advanced manufacturing champion. We believe these cases will put the wind at our back and provide the right policy environment to execute our business plan.”

T1 Energy has historic form in supporting tariffs. Barcelo said that Donald Trump’s “reciprocal” global tariffs announced earlier this year “dovetail with” T1 Energy’s strategy, and anticipated “financial benefits” from the scheme.

Analysis: The impact of tariffs

Last week, energy market intelligence firm Wood Mackenzie warned that targeted tariffs on polysilicon were the biggest “supply vulnerability” facing the US solar sector, and could “choke the entire US solar market.”

The US currently has relatively little polysilicon capacity, and zero operational solar ingot or wafer capacity, which are the supply steps between polysilicon and solar cells. Those facilities take years to build, which Woodmac said could lead to supply shortages if the global market (which is overwhelmingly dominated by China) becomes less accessible to US companies.

As with the changes to tax credits for renewable energy, the actual impact of tariffs on the US solar sector isn’t yet clear.

In contrast to Wood Mackenzie, PV Tech heard from a leading industry analyst that potential tariffs on polysilicon might have a limited impact because the price of polysilicon and its derivatives—like solar wafers—is so low. Wafer prices have been as low as US$0.02 per watt recently; a 50% tariff would make the price US$0.03 per watt.

While this assessment doesn’t represent a severe vulnerability, it also offers little towards T1’s claim of the potential tariffs “boosting American advanced manufacturing”.

There is precedent for AD/CVD cases in the solar industry. Many in the sector have opposed them, saying they can cause uncertainty and supply bottlenecks. There have been two in recent years, focused on modules and cells coming from Vietnam, Malaysia, Cambodia and Thailand via Chinese-backed companies.

Woodmac said the AD/CVD for cells caused a 12% increase in module prices year-on-year, and industry consultancy Clean Energy Associates (CEA) forecast a “bottleneck” in solar cell supply as a result of the measures.

Supply of solar cells from countries that have not been subject to AD/CVD investigations is scarce, which is likely to increase the price of cells in the US market and ultimately increase the price of modules. Combined with the changes to incentives under the budget reconciliation bill, which make it harder to access tax credits both for building US solar manufacturing capacity and buying modules with domestic content, the majority of solar manufacturers in the US will be challenged to keep their costs competitive.

In comments to PV Tech, Aaron Halimi, head of developer Renewable Properties, said that while developers “want to buy US products”, financial realities will ultimately dictate their decision.

“At a certain point, we’ll have to weigh the costs of tariffs and US domestic content,” Halimi said. The domestic content bonus for using US-made products is available to developers until the investment tax credit (ITC) ends next year.

He continued: “One way or another, we want to build our projects, and if the economics are better for procuring equipment from outside the US, we’ll have to do that to reduce the impact on our costs and ultimately for electricity prices.”

The latest edition of our quarterly journal, PV Tech Power, leads with an in-depth analysis of the changing fortunes for US solar, including the impact of tax changes and tariffs on manufacturers.