The solar industry is at a tipping point with terrain-following trackers. This innovative technology is transforming solar installations by significantly reducing grading requirements and mitigating a range of vexing environmental concerns. Now poised for wider adoption, this innovation is expanding the viability of solar projects to a greater variety of landscapes.

Using the land as it is given to us

Until recently, extensive grading was usually required to establish a level gradient on land used for utility-scale solar installations. This essential step enabled proper alignment of the rigid mechanical structures that needed to be built in a single plane.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Grading, however, is labour-intensive and costly and introduces the risk of unknowns to a project, often requiring rework and remediation above initial estimates of total earthwork. Moreover, this earthwork disrupts the natural landscape, substantially increases the project’s carbon footprint and requires extensive remediation of disturbed areas through reseeding and other vegetation management.

Terrain-following trackers are specifically designed for optimal function on uneven or sloped terrain. By conforming to the natural contours of the land, terrain-following trackers maximise the energy captured by solar panels, significantly reducing grading requirements, sometimes by as much as 100%, though typically between 70% and 80%.

Terrain-following trackers are not new. They were introduced in the early 2010s and made commercially viable for utility-scale projects in 2019. Innovative solar tracker manufacturers have used them to broaden the range and suitability of sites for solar projects that were not previously considered for development. However, initial adoption was slow due to developers’ preferences for flatland installations, and like other disruptive technologies, they were less inclined to switch without a proven track record and installation.

As more sustainable solutions in solar construction are implemented, we are seeing new environmental regulations emerge, including grading restrictions aimed at minimising land disruption and preserving natural ecosystems.

Opening up challenging sites

Today, with premium sites for solar developments increasingly difficult to find, terrain-following systems are becoming the go-to technology.

At Burns & McDonnell, more than half of solar projects currently in design or construction incorporate terrain-following trackers. This is a dramatic increase from as recently as 2023, when these systems were rarely specified. This growing popularity, especially on larger-scale projects exceeding 200MW, can be attributed to several factors:

- Lower costs: On larger installations that would require extensive grading with conventional systems, terrain-following trackers offer a more favourable value proposition on many projects. It is prudent and highly recommended to perform a cost analysis of installation size, terrain complexity, labour costs and other project-specific factors to verify the overall benefits. For two solar projects now under construction by Burns & McDonnell in Illinois and Michigan, for example, the cost analysis showed that grading expenses exceeded the purchase and installation costs of terrain-following tracking equipment. In both cases, the analysis showed that using terrain-following trackers would reduce the amount of earth to be moved from more than 250,000 cubic yards to less than 50,000 cubic yards. Additionally, the use of these trackers decreases the installation time spent by crews in the field.

- Greater sustainability: Bulldozers and other heavy equipment used to level solar sites and seed groundcover consume significant amounts of diesel fuel and create a sizable carbon footprint. In addition to minimising the civil work required, terrain-following trackers can also potentially reduce the amount of steel needed for foundations, resulting in more sustainable solar installations.

- Fewer environmental risks: A site’s topography reflects the weather events and geological processes that shaped it. By preserving the natural landscape and existing topsoil, terrain-following trackers help maintain existing site drainage patterns and vegetation — minimizing erosion and stabilization risks, as natural water flows follow their original paths and natural vegetation keeps the soil stabilized.

How terrain following trackers work

With conventional tracker systems, extensive site levelling is often required prior to pile installation because the tubes holding the panels and trackers must be installed in a straight line.

Tests on Nextracker’s NX Horizon XTR projects of both the mechanical and structural components, as well as the effect on the drive system, have shown that a certain amount of natural bending can occur with no negative impacts. The real technology breakthrough was a demonstration that bending on NX Horizon XTR projects occurs naturally during field installation with no requirements for fabrication equipment for material bending because the tubes will naturally follow the contours of pilings as they are set in the ground.

While there may be some additional costs for larger and heavier-gauge tracker components, these added costs are only a fraction of the savings that can be expected from reduced need for grading, labour and other site work.

On a utility-scale solar project currently underway in Illinois, the earthworks associated with tracker installation on the site has been nearly eliminated because of the NX Horizon XTR tracker that is being installed combined with slightly higher pile heights.

Impact on site considerations

Commercial solar farms are typically built on farmland chosen for their smooth and flat terrain with favourable landscape. Many prime locations in Texas, the South and Southwestern US have already been converted to solar farms, prompting developers to explore more opportunities in the Midwest, where demand for renewable energy is growing and land availability is often greater.

When considering options, developers should weigh a range of factors concerning the use of terrain-following trackers. It is crucial to understand the technological capabilities and operational limits of the terrain-following trackers currently on the market. For instance, slope gradients on most sites generally do not exceed 10% due to constructability or safety concerns.

Cost savings and reduced carbon footprint

Because single-axis terrain-following trackers have the flexibility to follow the natural grade of a site, they reduce the need for extensive grading and mitigate many of the risks associated with erosion, ground disturbances and construction.

On a recent project location in Australia, land use restrictions on a First Nations Aboriginal Heritage site meant that a terrain-following tracker was the only feasible option. Similar restrictions on grading and site work can be expected on the 30 million acres of environmentally sensitive land in the western US that have been recently opened for solar development by the US Bureau of Land Management.

Studies have shown that terrain-following tracker systems require up to 9,000 lbs. less steel per megawatt of output and 6,000 less cubic yards of grading per megawatt.

The cost savings and reduced carbon footprint associated with terrain-following trackers are now tipping the scales in their favour among solar project developers and engineering, procurement and construction (EPC) contractors.

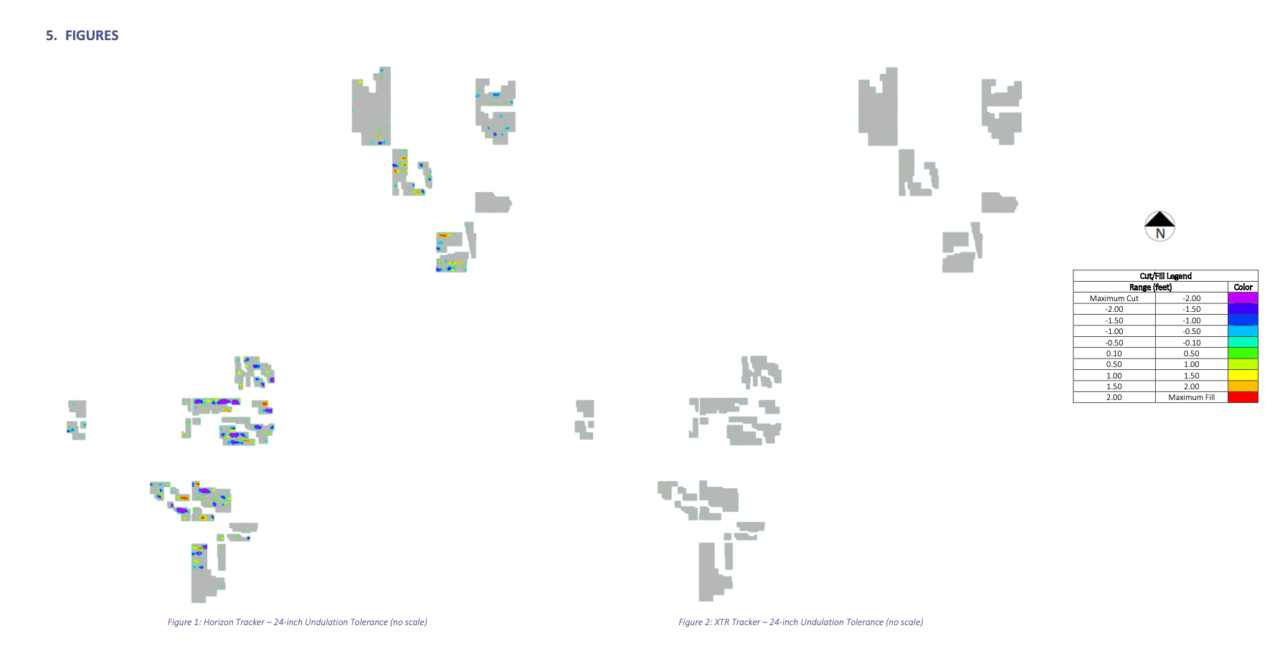

All projects hinge on understanding the topographic variables specific to each solar project, and terrain-following tracking solutions are no exception. Preliminary site analyses should provide a detailed map of all site variables in order to align with the developer’s financial objectives, risk tolerance and sustainability goals.

Dalton Ruddell, PE, is a renewables development engineer who helps lead pre-construction efforts in the solar group at Burns & McDonnell. Nick Price is a senior director of global sales engineering at Nextracker.