PV module manufacturer Suntech has signed a cooperation agreement to build a 10GW tunnel oxide passivated contact (TOPCon) high-efficiency cell production manufacturing hub in the Chinese province of Anhui.

With a total investment of RMB10.5 billion (US$1.52 billion), the company will partner with the municipal government of Suzhou City and Suma Park of Suzhou City.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

The company currently has production bases in Wuxi, Changzhou, Chuzhou and Suzhou, with an annual cell capacity production of 16.5GW and a module production capacity of 25GW annually.

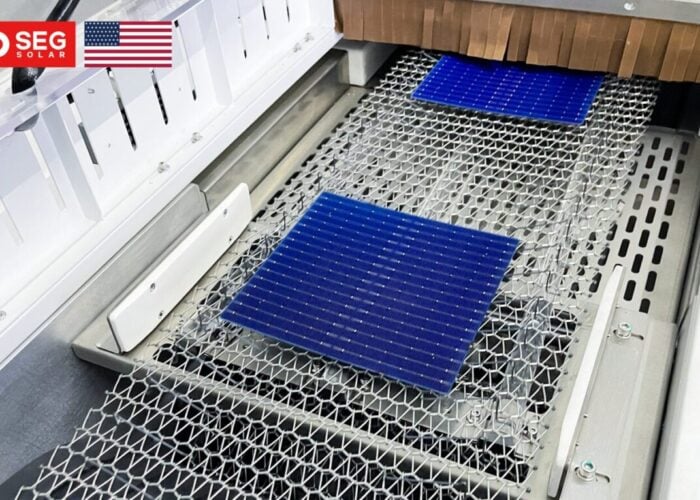

Suntech’s smart factory will be able to produce 182mm (M10) and 210mm (M12) cells for the production of n-type TOPCon modules.

Moreover, the PV module manufacturer is among several Chinese manufacturers who recently announced an increase in production of n-type TOPCon modules with module manufacturers Trina Solar and DAS Solar also betting on the technology.

Recently PV Tech Premium explored the levelised cost of energy for different technologies of n-type modules including TOPCon, passivated emitter and rear cell (PERC) and heterojunction.