Late last year AES Corporation unveiled the Atlas, an automated solar deployment robot the company claimed to be a first of its kind. Here, AES gives PV Tech Power the full story of its development.

To address the most significant challenges posed by climate change, the world must achieve net zero emissions by 2050. To reach that goal, governments, businesses and communities need to change the approach to seven emission-emitting infrastructure systems: energy, industry, mobility, buildings, agriculture, forestry, and waste.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

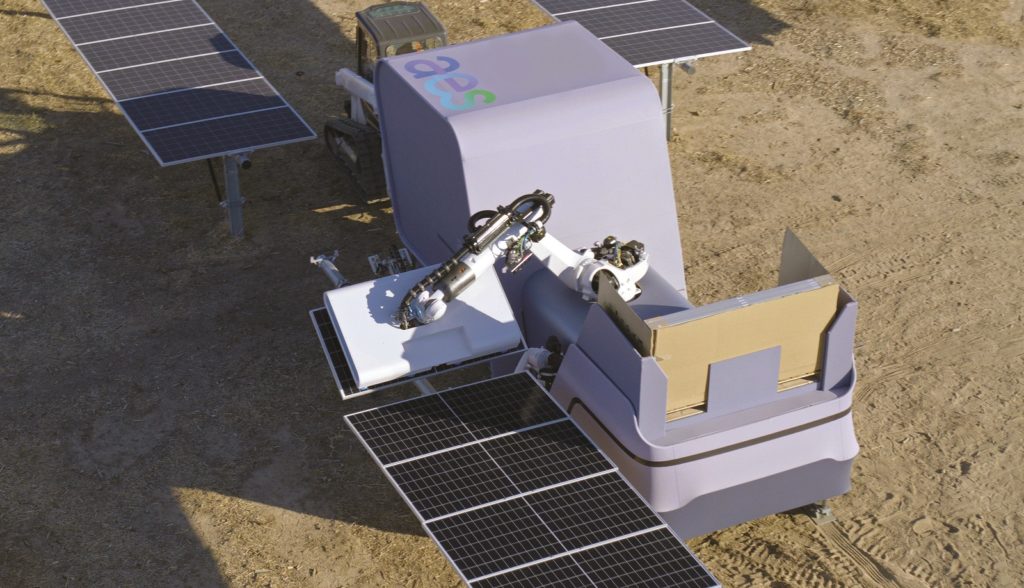

Accelerating the deployment of renewable power at scale is an essential part of this change, and this requires reimagining the way we install solar. At AES, we are rising to this challenge, increasing the speed of solar deployments, addressing workforce shortages, and promoting safety and inclusivity with Atlas, our recently launched automated solar installation robot.

We are also addressing land constraints and construction timelines with our investment in 5B, a clean tech innovator focusing on prefabricated solar technology.

Unprecedented solar growth

Today, the power sector accounts for about 30% of global CO2 emissions. To achieve net zero by 2050, nearly all this power must be generated by renewable energy. Moreover, the systems that are currently powered by fossil fuels—particularly mobility, industry, and buildings—will need to transition to electricity. In some cases, this will happen directly through the adoption of new products and technologies like electric vehicles and heat pumps, whereas other systems will electrify indirectly, consuming fuels that are produced from electrically generated feedstocks such as green hydrogen.

As a result, by 2050, the demand for electricity will increase to two to three times what it is today [1] — and that increased demand will primarily be met by solar energy. This represents an unprecedented opportunity for solar expansion and necessitates fast paced construction of large-scale solar facilities. The Solar Energy Industries Association (SEIA) estimates that in the US alone, achieving the Biden administration’s goal of 100% clean electricity by 2035 will require the annual deployment of more than 130GW of solar, a five-times increase from the 24GW added in 2021.

Globally, the International Energy Agency (IEA) estimates that annual solar deployment will need to increase from the 183GW installed in 2021 to more than 630GW by the end of this decade [2].

We need to change how we do things

This poses significant challenges — and opportunities — in a construction industry that is already facing workforce shortages [3]. In the absence of changes in the ways solar photovoltaic plants are installed, the segment of US workforce dedicated to solar construction will need to quadruple, from the 230,000 solar workers today to more than 900,000 workers by 2035 [4].

A single utility solar plant may require the installation of several hundred thousand solar panels. Staging, placing, and securing panels onto mounting structures represents some of the most repetitive and time-consuming processes in solar installation. Atlas was designed to assist the already-stretched workforce by completing these tasks, increasing the installation rate to enable shorter construction timelines, all while growing high-quality installation jobs.

In addition to this material workforce expansion, the solar industry will need to manage increasing safety constraints in the coming years, which automated installation can mitigate. The solar industry is moving towards larger, high-capacity modules. New module manufacturing standards will help to improve efficiency and delivering the optimised project economics that are needed to support the acceleration of solar expansion.

However, although larger modules save labour expenses, balance of plant cost, and allow for a more efficient use of land, they also add considerable weight. New module standards weigh up to 50% more than the previous industry standard and create a 60% larger surface area that makes them harder to lift and handle [5]. Atlas does this heavy lifting for solar installers, increasing safety and supporting inclusivity by reducing physical strength requirements for solar installers.

Apart from heavier lifting, solar installers are also likely to face hotter installation conditions [6,7]. By mid-century, the National Weather Service estimates that four times as many US cities will experience 30 or more 100+-Heat-Index-days, and that extreme heat waves are likely to become more frequent [8].

Given that high-insolation sites with little shade produce optimal solar output, solar is often deployed in harsh-weather, high-temperature areas. As a result, our industry employs significant protective measures to prevent heat-related illness. In the coming years, such efforts to keep the solar construction workforce safe from heat-related illness will become increasingly important, impacting construction operations and project timelines.

Safety is our number one priority, and by automating the panel installation process, we can limit personnel exposure and strenuous activities in high heat index conditions, while accelerating the pace of deployment and shortening the construction timeline.

Driving automation

AES’ purpose is to accelerate the future of energy, together. We set out to reimagine solar installation to make it safer, faster, more affordable, accessible, efficient and scalable. This led us to develop Atlas, a first-of-its-kind artificial intelligence-enabled solar panel installation robot. We designed Atlas through a multi-year innovation process and built it in cooperation with our partner Calvary Robotics, along with other third parties.

Atlas is a tool to assist the solar installation workforce; it automates the repetitive and manual steps of the solar panel installation process. Atlas installs solar panels in half the time required for current fully manual methods. This reduces construction timelines while improving safety by minimising heavy lifting and creating better working conditions in harsh climates.

Automation in controlled and structured environments, such as factories, has been around for decades. In the solar industry, robotics and advanced manufacturing techniques have been used in the four steps of module manufacturing: silicon ingots, wafers, cells, and modules. In the field, simple robotic applications such as robotic automated mowers and photovoltaic module cleaning robots are increasingly common.

In recent years, advancements in artificial intelligence, computer vision, mobile robotics, and advanced sensing for navigation, positioning and detection in dynamic environments have enabled advanced robotics and automation applications that would not have been possible just a few years ago. From self-driving cars to autonomous agricultural and construction machinery, outdoor automation in unstructured environments is now a reality.

We evaluated these technological advancements, tracked them over time, and incorporated advanced robotics and computer vision into Atlas. Rather than starting with the simplest installation tasks, we focused on the most repetitive steps in the process. Our aim was to prove that Atlas could overcome the most difficult challenges, helping to boost confidence and enabling Atlas to scale.

This first-generation of Atlas robots are comprised of one robotic arm that picks and places the photovoltaic modules onto the solar structures and their respective clamps. Its computer vision system enables Atlas to “see” the solar structure and clamps. It then calculates its position relative to the torque tubes and determines where to place and secure the module. Atlas’ second robotic arm finalises the installation process by locating and torquing the bobtail of the clamp, allowing for a complete installation of the solar panel.

The Atlas robot was designed to be PV structure and photovoltaic module agnostic; its artificial intelligence allows it to be trained on different solar structure and panel combinations. Solar panel mounting hardware is designed for humans, not robots. We designed Atlas to work with these existing, commercially available mounting systems, rather than developing a new tracker and clamp design for optimal automated deployment.

Although developing such a tracker would have simplified Atlas’ design and operation, it would have required solar developers and installers to introduce a new mounting product, creating complexity and constraining Atlas’ reach. As we scale, we may be able to further accelerate by influencing the supply chain to provide mounting hardware that is optimised for automated installation.

Together with our partners, we are further developing Atlas’ capabilities by rolling it out within AES’ solar pipeline. Atlas will continue to gather experience, expanding the module and tracker system combinations that it can work with. Improvements in performance is one of the key focus areas to continue challenging Atlas to meet our vision. Atlas’ capacity and versatility will continue to grow as it builds more solar projects across a greater variety of topologies.

We are executing on Atlas’ technology roadmap, and in collaboration with talented teams to iterate and improve Atlas. We will continue to expand the fleet to take on more and larger projects. We are committed to our purpose of accelerating the future of energy, together, and we are excited to bring Atlas to the solar industry to help unlock the speed of solar deployment the world needs to meet net zero emissions.

Authors

Ashley Smith, chief technology & innovation officer, AES

Deise Yumi Asami, solar transformational designs director, AES

Alvaro Creixell, solar construction innovation project manager, AES

References

[1] IEA, “World Energy Outlook 2021, Dataset”.

[2] IEA, “Net Zero by 2050 A Roadmap for the Global Energy Sector”. May 2021

[3] PV-Tech.org, “Renewables firms ‘risk talent exodus’ amid skills shortage fears.” March 2022.

[4] SEIA, 11th Annual National Solar Jobs Census 2020. May 2021.

[5] PV Tech.org, “DNV analysis on BOS cost of large format modules shows slight advantage of 182mm module”. October 2021.

[6] National Centers for Environmental Information, “Assessing the U.S. Climate in August 2021”. September 2021.

[7] World Weather Attribution, “Western North American extreme heat virtually impossible without human-caused climate change.” July 2021.

[8] National Geographic, “Off-the-charts’ heat to affect millions in U.S. in coming decades.” July 2019.