Aurora Solar Technologies has introduced the ‘Veritas Insight’, a new product that is designed to provide a fully integrated quality control system for high-efficiency solar cells such as PERC (Passivated Emitter Rear Cell).

Problem

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

There are a number of challenges facing cell manufacturers in characterizing and controlling production variation of high-efficiency solar cells. These variations cause yield limitations and profit loss, and can introduce excess warranty liabilities, due to poor electrical performance and other variances in finished cells. The effects can also be seen in the often-lengthy time it takes to bring new high-efficiency production lines up to speed, resulting in many weeks of suboptimal performance. Manufacturers therefore need to make use of the powerful information embedded within the enormous quantity of production data being generated as the industry scales to hundreds of gigawatts of annual production and make actionable information to boost manufacturing yield and detect hidden process behaviour that affects product quality.

Solution

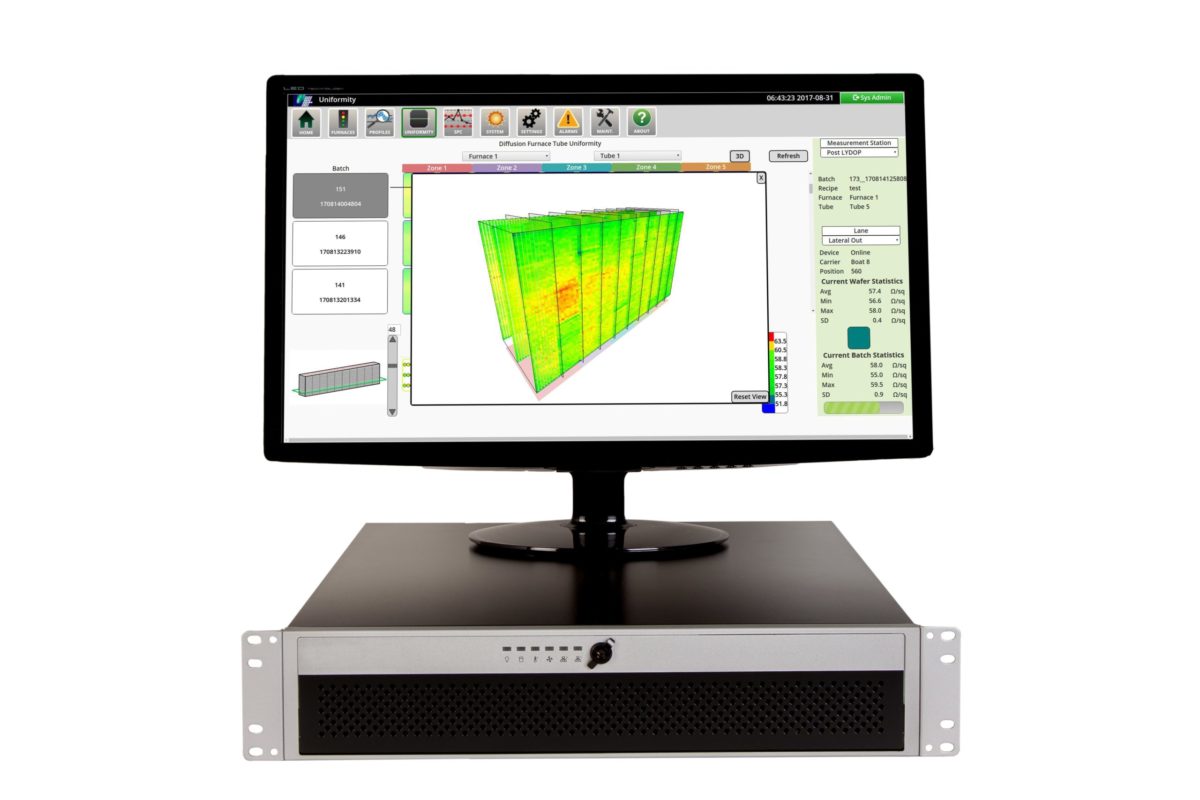

Leveraging extensive research and experience with actual solar cell production line variance and their root causes, Veritas Insight directly addresses these problems. Surpassing traditional Statistical Process Control methods, it detects and interprets complex process deviations or faults that cannot be directly discerned, but cause protracted declines in average efficiency or costly quality issues in the field. It reveals causal relationships between finished cell electrical variations and controllable upstream fabrication process variations in real-time. This allows production personnel to see, understand and manage trade-offs and fluctuations as these occur in production. Veritas Insight provides these benefits with end-of-line cell performance alone or in combination with other production line measurements.

Applications

Fully integrated quality control system for high-efficiency solar cells such as PERC, bifacial, heterojunction (HJ) and other cell technologies.

Platform

Veritas Insight provides end-of-line cell analysis or in combination with other production line measurements.

Availability

Veritas Insight will be available starting in April 2018.