Graphene manufacturer First Graphene revealed a supply agreement yesterday (27 September) with Australian perovskite solar cell manufacturer Halocell Energy to provide a new coating product.

Under the terms of the two-year agreement, First Graphene will supply its PureGRAPH product for incorporation into Halocell’s perovskite solar PV cells. According to the companies, this coating grants enhanced light-absorbing qualities and helps the company scale up commercial production.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Specifically, the coating will likely be used in Halocell’s upcoming indoor perovskite solar PV cell module, its first commercially available product. This module can charge various small electronic goods with renewable energy.

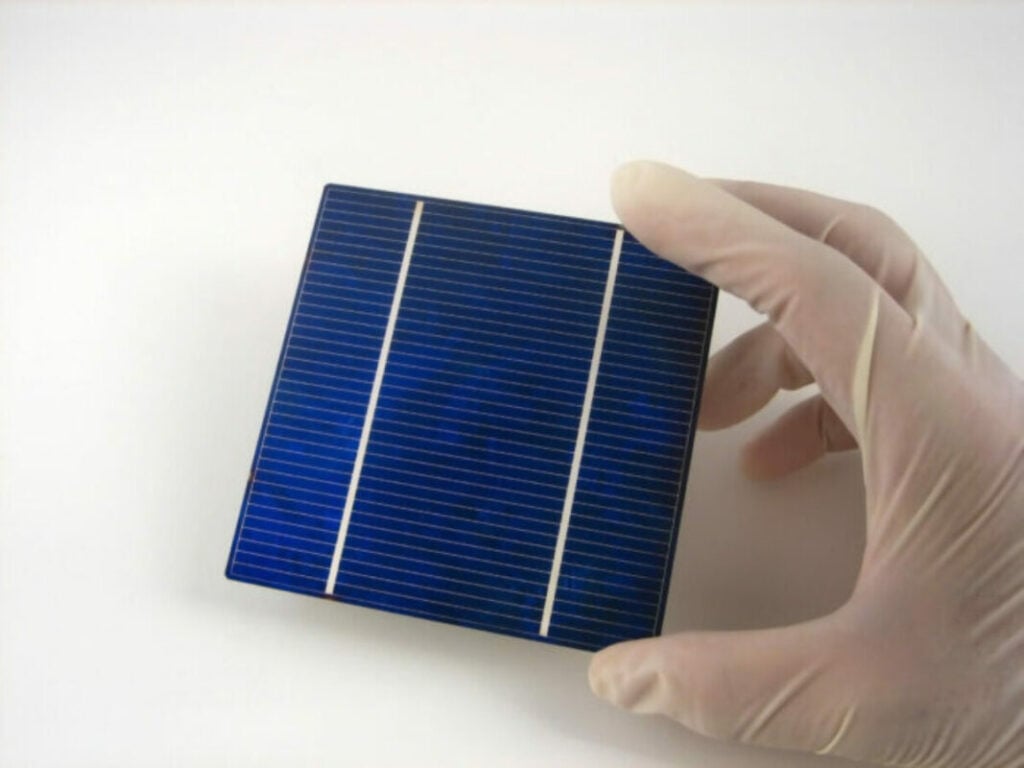

Graphene is an alternative option for solar cells with various enhancement features. For instance, due to graphene’s exceptional electrical conductivity and thermal properties, there is good potential for improved energy conversion efficiency.

Because of this, the graphene-enhanced modules are five times more efficient than conventional silicon solar cells, the manufacturer claimed. First Graphene also said that these solar cells are more cost-effective and can reduce manufacturing costs by over 80%, eliminating high-cost conductor materials such as gold and silver.

Halocell claimed the release of its first commercially available indoor perovskite solar cell module is imminent.

The Australian Renewable Energy Agency’s (ARENA) is aiming to support the development of ultra-low-cost solar in the country to aid its renewable energy expansion. ARENA argues that a ‘30-30-30’ approach to solar, representing 30% solar module efficiency and an installed cost of 30 cents per watt by 2030, could help Australia become a renewable energy superpower. This would also mean achieving a levelised cost of electricity below AUS$20 (US$13.75) per megawatt hour by 2030.

The graphene formulations will allow for the use of roll-to-roll dispersion, which is a fast, scalable, and cost-effective production technique for making PV solar cells. This technique is being researched and developed via a collaboration between First Graphene, Halocell Energy, and Queensland University of Technology.

Paul Moonie, CEO of Halocell Energy, hailed the supply agreement with First Graphene, stating that it marks a “significant step forward for Halocell in developing cutting-edge PV solar cells”.

“By leveraging First Graphene’s advanced graphene formulations, we can optimise particle size and surface chemistry, enhancing the efficiency and scalability of our solar cells. The integration of these locally supplied materials into our roll-2-roll production process enables cost-effective, rapid manufacturing, which will be a game-changer for the solar industry in Australia,” Moonie added.