While bifacial modules promise advantages in power production, they can create complex performance monitoring challenges. That will need to be resolved if project production uncertainties are expected to remain at levels and expectations currently set with the deployment of mono-facial modules, write Ajay Singh and Derek Jones of Campbell Scientific Inc.

Bifacial PV modules can produce electrical energy by absorbing light from both front and rear sides of the module, resulting in an additional gain of 10-15% more electrical energy output.[1] The primary difference between bifacial modules and traditional monofacial modules is that the rear side of the cell also has a grid pattern for contact rather than completely covered by an aluminium contact. A glass or another transparent backsheet is used behind the solar cells to capture light reflected from the ground. More and more PV manufacturers are offering these modules and they are gaining marketplace acceptance. The additional gain depends on the amount of reflected light (albedo) reaching the rear side, which is highly dependent on the local site layout, ground cover, height of modules from the ground, distance between modules in a row, the distance between the rows, the time of day and the time of year. There is an increased uncertainty in energy forecasts due to the variabilities in albedo resulting from all these factors. These uncertainties compound the complexity and uncertainty of project design and can even be a hindrance in the adoption of bifacial modules in the industry and hence have attracted a lot of research interest recently.[2]

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Measuring incoming, front-side irradiance, is relatively simple compared to reflected irradiance on a site in that for a particular site under clear sky conditions the incoming irradiance will be spatially uniform at a given time, while reflected or rear-side irradiance can vary as acknowledged above and be confounded by other factors like racking. The solar PV community recognises the need to monitor rear-side irradiance and international standards organisations like the IEC have provided definitions and recommendations for monitoring rearside irradiance. In IEC 61724-1 2021 there is guidance for the type, spacing and orientation of sensors for monitoring rearside irradiance and horizontal albedo. Even following the provided monitoring recommendations provides limited spatial coverage which may or may not be representative of the entire site.[6,7]

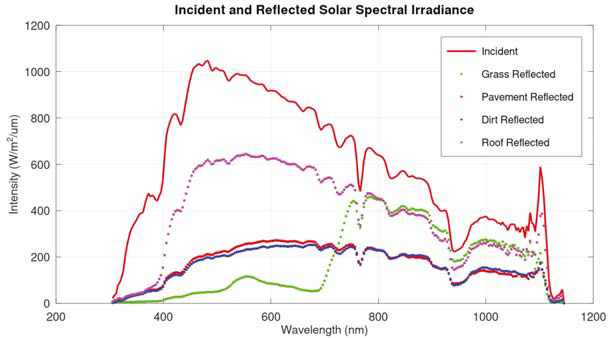

Measurement of power production losses due to PV module soiling on bifacial modules is another area that is very important and suffers from variability and complexity of the albedo and rate of PV module soiling at a site. This is all compounded due to the spectral mismatch of incoming and reflected irradiance which can vary over time and depends on the ground cover, racking and current ground conditions.[3-5] Figure 1 shows the spectrum of reflected sunlight from different ground surfaces. Another challenge is the anticipated differences in the rate of soiling on each side of a module (front and rear), and the fact that a bifacial module has only a single power output which gives no insight into irradiance or soiling losses to power production from incident versus reflected light.

There is still no clear consensus on the best methods to be used to determine losses due to soiling of bifacial PV modules. To date there is still no consensus on the best methodologies to measure soiling on mono-facial panels and for reasons discussed above bifacial panels add to the confusion around this topic. There are optical sensors that promise easy installation and relatively maintenance-free operation, but the data quality from these sensors has been questionable and does not correlate well with the production losses reported in the plant production data. Another methodology compares the output from two PV devices, one clean and one soiled. This methodology provides a soiling loss index (SLI) that best correlates to plant performance but requires expensive periodic maintenance and can be burdensome to implement. This method becomes more complex for bifacial modules for reasons mentioned above, as well as the fact that these panels have only one output and the contribution from the front and rear side cannot be separated easily.

Some early adopters of bifacial PV technology used four collocated modules with different cleaning routines to determine soiling losses and to understand the different soiling rates of the front and rear sides of the modules. One module was cleaned regularly on both sides, a second was cleaned only on the front side (rear side left to soil naturally), a third was cleaned only on the rear side (front side left to soil naturally), and the fourth module was left to soil naturally on both sides. While this method is cumbersome, and the maintenance requirement is tedious it provides a good overall soiling rate, including separate rates of soiling for the front and rear sides which gives plant operators more useful information. In practice it is rarely implemented due to spatial limitations and maintenance requirements.

Another approach for monitoring soiling losses on projects using bifacial PV modules is to follow the Method 2 guidance in the IEC 61724-1 2021 and to compare the output from one clean panel to the output of a soiled panel assuming that on an average they see similar reflected irradiance.[8] If this method is deployed it is recommended that care should be taken to maintain the ground conditions the same behind both the panels. If all parameters are held equal behind two bifacial modules this methodology can be successfully implemented, but the operator will be left with a single SLI but with no insight into front versus rear side soiling.

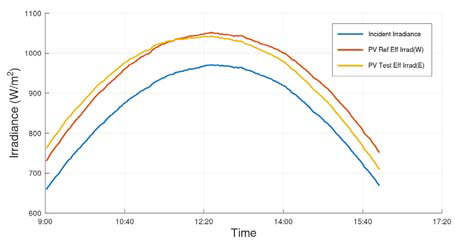

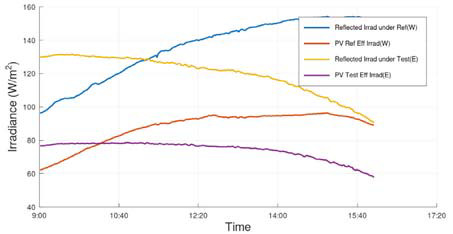

In a recent study Campbell Scientific Inc. proposed a method to separate the contributions of incident and reflected irradiance from the output of bifacial modules and determine power losses due to soiling on the front and rear sides of a bifacial module. Two identical bifacial PV modules were installed side by side at the same tilt. Module performance on both modules was monitored following Method 2 outlined in Annex C of the IEC 61724-1 2021, wherein one module is maintained as a clean reference and the second is left to soil naturally. In our study short circuit current and temperature of these two modules were measured and an effective irradiance was calculated.[9] Additionally, in this study reflected irradiance was measured underneath each bifacial module with a small low form factor silicon pyranometer adhered to the centre of the rear side of each module. This was possible due to the use of half-cut cell PV modules deployed in this study.

To draw a correlation between front and rear-mounted irradiance sensors and the output of the bifacial PV modules, on a clear sky day, the front side of the modules were covered with an industrial grade thick black plastic sheet (thickness 0.15mm). This was temporary and the measured output of the modules in this state can be attributed to the rear-side contribution only. An in situ bifaciality gain can be deduced from these measurements and used in calculating front-side and rear-side soiling losses moving forward.

The aim of this study was to gain insight on and also to explore a methodology to separate the contributions to module output from front and rear sides. This method allowed the calculation of an overall SLI and individual SLI for each of the front and rear sides of the bifacial PV modules within the uncertainty of the measuring equipment. The results from this study were promising; the overall losses from soiling were dominated by soiling on the front side as expected, while the soiling loss on the rear side was minimal and may be affected by the spatial variations in the albedo across the two modules under comparison.[2] While the results from the study provided additional insights it is unclear if the methodology would be generally accepted in the industry. Sites with seasonal variability might also need to repeat covering the front of the modules for a seasonally dependent bifaciality gain factor which would be an additional hindrance to the widespread adoption of this method in practical applications.

In summary, while bifacial PV technology promises advantages in power production it creates performance monitoring challenges that prove to be complex, but that will need to be resolved if project production uncertainties are expected to remain at levels and expectations currently set with the deployment of mono facial PV modules on projects. The variability of reflected irradiance and soiling of PV modules over time and location will impact production and development of a project significantly impacts the site environment contributing to both of these factors. Either project owners and developers will learn to cope with higher yield uncertainties or new and better methodologies for quantifying production performance from bifacial PV modules will need to be developed.

References

[1]. Kelly Pickerel, “What are bifacial solar modules”, Solar Power World, April 2018.

[2]. Jenya Meydbray, “Hurdles to widespread bifacial PV adoption,” PVTech.Org, December 2018, pp 64-68.

[3]. Rob W. Andrews and Joshua M. Pearce, “The effect of spectral albedo on amorphous silicon and crystalline silicon solar photovoltaic device performance,” Solar Energy, vol. 91,2013, pp. 233-241.

[4]. M.P. Brennan, A.L. Abramase, R.W. Andrews, J. M. Pearce, “Effects of spectral albedo on solar photovoltaic devices, Solar Energy Materials and Solar Cells,” vol. 124, 2014, pp. 111-116.

[5]. Thomas C. R. Russell, Rebecca Saive, Andre Augusto, Stuart G. Bowden, and Harry A. Atwater, “The Influence of Spectral Albedo on bifacial Solar Cells: A Theoretical and Experimental Study,’’ IEEE J. of Photovoltaics, vol. 7, November 2017, pp 1611-1618.

[6]. Guillaume Razongles, Lionel Sicot, Maryline Joanny, et al. “bifacial photovoltaic modules: measurement challenges,” Energy Procedia, vol. 92, 2016, pp 188-198.

[7]. Enric Grau Luque, Fernando Antonanzas–Torres, and Rodrigo Escobar, “Effect of soiling in bifacial PV modules and cleaning schedule optimization,” Energy Conversion and Management, vol. 174, pp.615-625, October 2018.

[8]. IEC 61724-1 “Photovoltaic system performance-Part 1: Monitoring, 2nd Edition 2021.

[9] Ajay Singh, Matthew Perry and Derek Jones, IEEE PVSC 2021, “Soiling on Bifacial PV Panel”.

Authors

Ajay Singh is a product manager in renewable energy group at Campbell Scientific Inc. He has a PhD in Physics and has worked in research and teaching Physics at university level for over two decades. Last seven years or so he has been working in solar PV energy at Campbell Scientific Inc. Soiling loss on PV panels is one of his focus areas of research.

Derek Jones is marketing development manager in renewable energy at Campbell Scientific Inc. He has been working the field for over 12 years. He has a master’s degree in environmental engineering.