With highly-reliable transparent PVDF film as the outer layer, hydrolysis/UV-resistant PET as the middle, and Cybrid’s exclusive fluoro-skin as the inner layer, Cybrid KPf is both pervious to light and weather-proof. The white mesh printing is realised by means of a continuous printing technique and the unique highly-reflective white coating. This solution has resolved defects brought about by the dual glass structure and has attained a patent.Bifacial modules have achieved rapid development in recent years, global installed capacity surging from 97MW in 2016 to 7GW in 2019.

According to the Wood Mackenzie Consultancy, bifacial modules will, by 2024, account for 17.2% of all modules in service. A conservative estimation suggests the technology’s capacity will exceed 21GW.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

There seems no doubt that bifacial high-efficiency PV will become the main force in the future. Major PV module producers have ramped up bifacial production and launched transformation programs one after another. For most manufacturers, it is relatively easy to transform their unifacial module facilities into those compatible with bifacial production.

The only issue is how to achieve it, using a glass or transparent backsheet?

There are different ways to frame bifacial modules, including dual-glass without frame, dual-glass with frame and glass+transparent backsheet+frame. Compared to the first two structures, the ‘glass + transparent backsheet + frame’ module stands out in terms of better satisfying the lightweight requirement of the market. Moreover, against the backdrop that larger-size wafers and modules are prevailing, the transparent backsheet provides manufacturers with the fastest yet safest way to transform.

Cybrid is a world-leading manufacturer of PV backsheets. At the end of 2019, the company’s total shipment of backsheets exceeded 100GW. As an industry leader, Cybrid is among the first to carry out transparent module R&D. The company started to supply its KPf transparent mesh backsheet to the European and Indian markets two years ago and recently it became available in the Chinese market.

Mark Wu, CEO of Cybrid Technologies, told PV Tech, “No equipment upgrade is required for the production of transparent backsheets and the cost of doing so is evidently very competitive in many ways. Besides being easy to install, our KPf transparent mesh backsheet replaces a piece of glass, remarkably reducing the weight of the module and increasing the rate of power by 5W.”

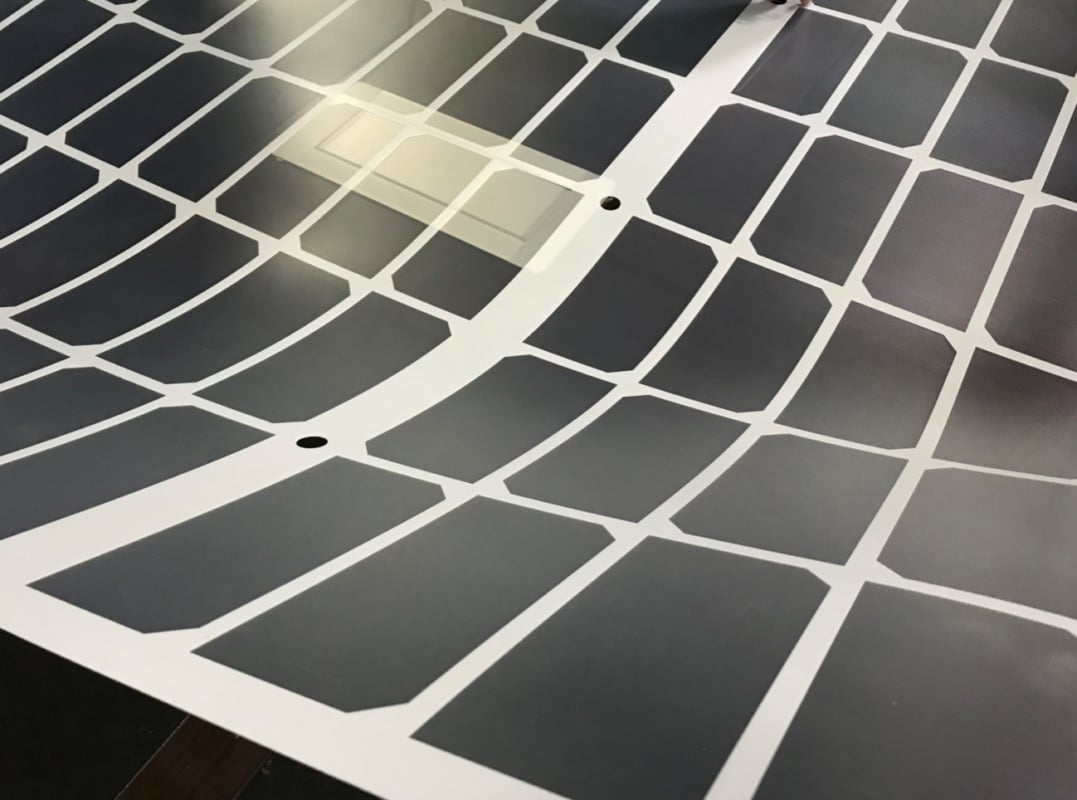

With highly-reliable transparent PVDF film as the outer layer, hydrolysis/UV-resistant PET as the middle, and Cybrid’s exclusive fluoro-skin as the inner layer, Cybrid KPf is both pervious to light and weather-proof. The white mesh printing is realised by means of a continuous printing technique and the unique highly-reflective white coating. This solution has resolved defects brought about by the dual glass structure and has attained a patent.

Tackling backsheet and silicon gel cracking

With R&D capabilities in high polymer chemistry, high polymer materials, manufacturing techniques and equipment, Cybrid is well known for its innovation in the industry. Apart from its solutions for bifacial modules, the company also helps power plants to solve major maintenance problems like backsheet and silicon gel cracking.

A PV module has to cope with a variety of complicated environmental conditions in its long service life. Its protective packaging material must therefore meet a very high standard. With an ever increasing number of power plants around the world, some are now faced with various problems which raises the level of risk for investors.

It is said that over 20GW of modules in power plants around the globe are at risk of backsheet cracking, and over 30GW at risk of silicon gel cracking. Water can leak inside the module directly through cracks on the backsheet or silicon gel and cause a short circuit. Furthermore, the corrosion of metal components will cause a dramatic decrease in power, reducing the economic benefits of a plant.

Cybrid offers an innovative maintenance solution program, called MoPro, which addresses these problems. Different maintenance plans can be offered depending on the varying reasons for aging, through to choice of high polymer material to rectify an issue. Easy to carry out and install, the solution program can efficiently prolong the life span of modules, and has already secured a patent.

Mark Wu told PV Tech, “Previously when plant investors found backsheets cracking, they could do nothing but inform the module supplier to send the modules back to the manufacturer. Now there is MoPro, they don’t have to replace the broken ones with new modules and the problem is solved. Many power plants in European countries like Spain have been running for over 10 years, and are now suffering from different levels of maintenance issues. Our MoPro service sees a significant growth in these markets.”

It is understood that Cybrid’s MoPro solution has been well received by the market, with the company’s tapes for repairing outer and inner layers already used by many clients. With a total shipment of over 1GW, Cybrid’s market share leads the world.

Cybrid is now looking at establishing a franchise system, with the MoPro service as its new business model. The company has formulated specific solutions and standard procedures by studying various failure models. Their first franchisee is in Japan, and negotiations with several European companies are underway. Cybrid is also looking for partners to develop the franchise business together in other markets around the world, especially in developed countries like the US.

Besides the PV industry, Cybrid has also achieved significant success in other fields. As the world’s second largest POE film producer, Cybrid has its POE business in over 20 countries and the company’s pioneering IGBT thermosetting laminated busbar film has changed the way these products are used around the world, this film now being widely used in inverters, OLEDs, smart phones and electronic vehicles.

The company was given the right to formulate a national standard for this material, the second time Cybrid enjoyed such an accolade, after they did the same for backsheets. This product has now been supplied in large quantities to global giants like CRRC, Beijing Automotive Group and CATL.

Mark Wu concluded: “We are proud that we are an innovative company. We have an innovative R&D center, and 12.5% of our employees are R&D personnel. Our company only has a history of 11 years, but our response to customer needs is extraordinarily fast and proactive. Cybrid has done a lot and provided many solutions to the PV industry. At first, we only supply backsheets, and then we developed new products for our clients based on our sales platform. Now we provide overall solutions and have professional technical service teams to support our clients.”