Fraunhofer ISE researchers are exploring the potential of medium-voltage PV technology to reduce the need for increasingly scarce and costly raw materials such as copper and aluminium.

Under a project dubbed “PVgoesMV”, the German research institute plans to build and operate two “world first” medium-voltage pilot plants using 3kV string inverters to test the technical and economic feasibility of the technology in large-scale PV plants.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

This shift in voltage is seen as a key route to reducing material and installation costs in PV systems.

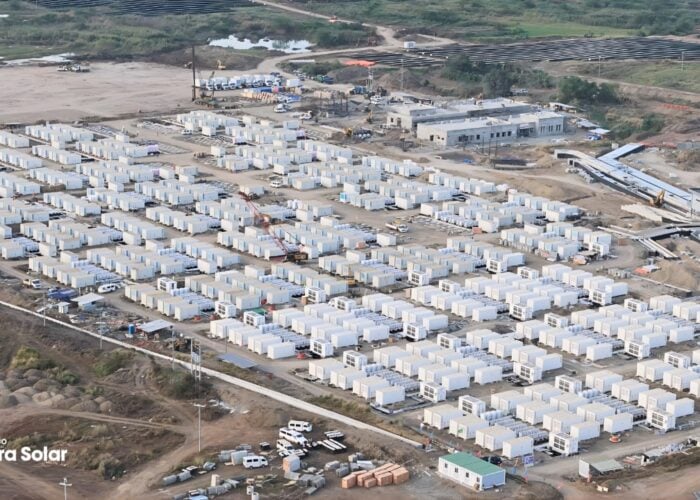

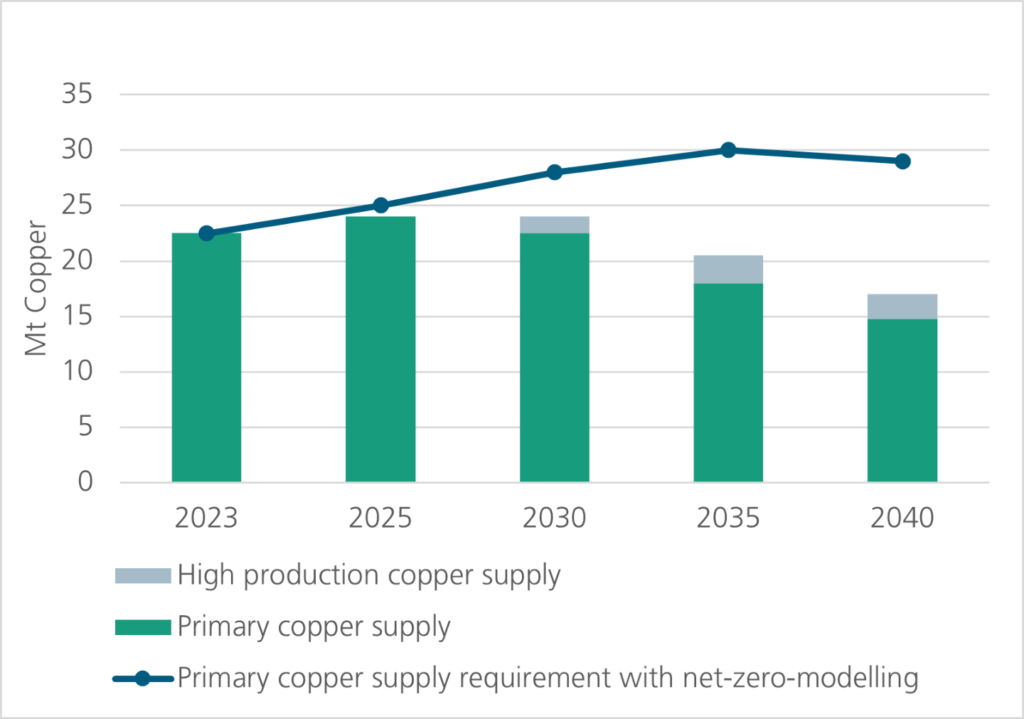

According to Fraunhofer ISE, a typical 50MW PV power plant uses cabling in the “three-digit kilometre range”. At the same time, data suggests that copper demand outstripped supply in 2025, driving prices higher. Aluminium is an alternative material in cabling, but production causes high CO2 emissions.

“The move to medium voltage is a key lever for reducing the demand for copper and aluminium in large-scale photovoltaic power plants and thus for the economic viability of the projects,” said project manager Felix Kulenkampff from Fraunhofer ISE.

Doubling the voltage of a project can reduce the cross-section of the conductor by up to 75%, Fraunhofer said. Thinner cables are easier to lay, meaning reduced installation costs. Meanwhile, because the connected load of transformers and substations can be doubled without changing their size, their number in larger power plants can effectively be halved, leading to further savings in material, investment and installation costs.

“All of the advantages mentioned are already apparent at low medium voltage. The costs of developing appropriately voltage-resistant components are manageable, which is why many component manufacturers are supporting us in the pilot project,” said Kulenkampff.

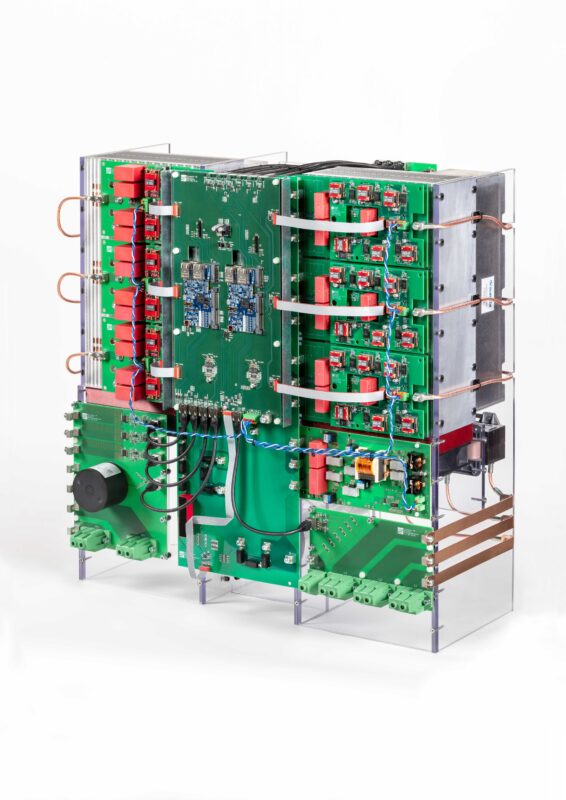

Fraunhofer ISE has already developed a silicon carbide-based medium-voltage string inverter under its MS Leikra project, and a version of this unit will be adapted for the pilot projects.

The two projects, in Baden-Württemberg and Rhineland-Palatinate, will each have a connected load of approximately 135kW and be tested over several months. They will be operated at 3kV on the DC side and 1.2kV on the AC side.

Two different string connections are being tested in the project. One will use standard solar modules with 1,500V and centre point grounding. The second will be based on a 3kV string using PV module prototypes specifically developed for higher-voltage class PV systems.

Fraunhofer ISE is working with a number of partners on the project, which are providing and developing its key components, as well as supplying expertise and engineering services for setup, commissioning and monitoring.

The partners are Pfalzwerke, the FEAG Group, Stäubli Electrical Connectors, Weidmüller Interface, Mersen Deutschland Eggolsheim, Prysmian Kabel und Systeme, Sumida Components & Modules GmbH, Hanwha Q Cells, Zimmermann PV-Steel Group, Infineon Technologies, Fluke Deutschland and BES new energy.

The ultimate aim of the project partners is to develop a quality assurance and testing concept for medium-voltage PV systems, incorporate findings from the field into their product design and contribute to international standardisation committees.

Construction of the pilot projects began in December 2025. The German government is providing funding for the project.