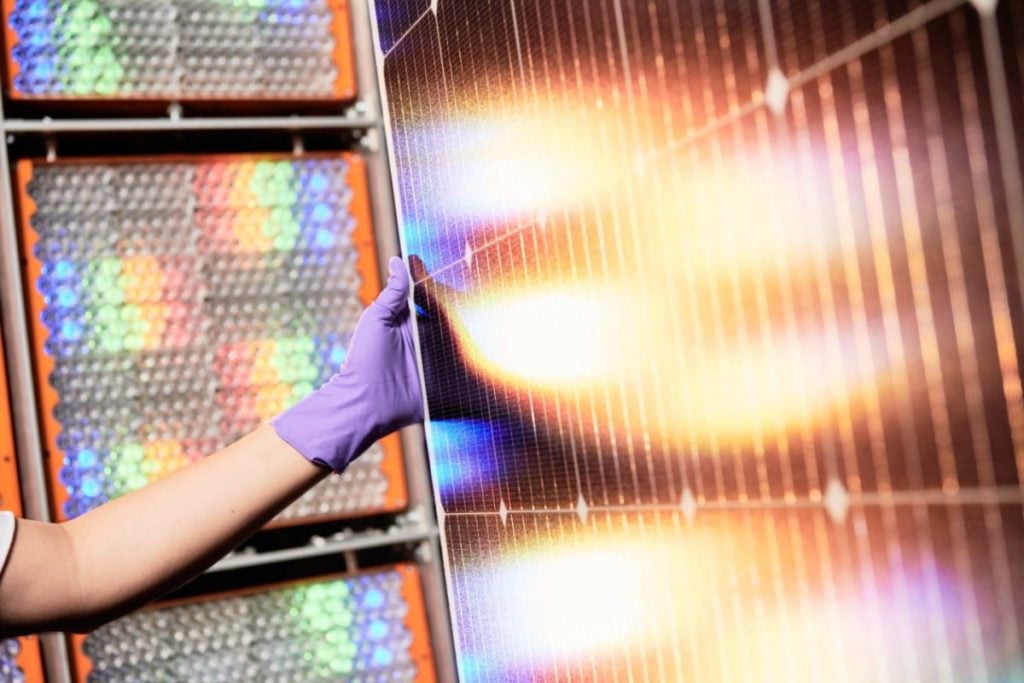

Perovskite solar cell researcher Oxford PV and German research organisation Fraunhofer Institution for Solar Energy Systems (Fraunhofer ISE) have developed a full-sized tandem PV module with a record efficiency of 25%.

The glass-glass tandem PV module produced by Fraunhofer ISE boasts an efficiency rate of 25% – related to the designated illuminated area – and an output of 421W on an area of 1.68 square metres, which is the world’s most efficient silicon perovskite tandem solar module in industrial format, according to Fraunhofer ISE.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

“This makes it more efficient than any silicon PV module ever built in industrial format. The fact that mass production-compatible technology was used for its manufacture demonstrates the enormous potential of tandem technology for the PV industry,” said Stefan Glunz, head of photovoltaics at Fraunhofer ISE.

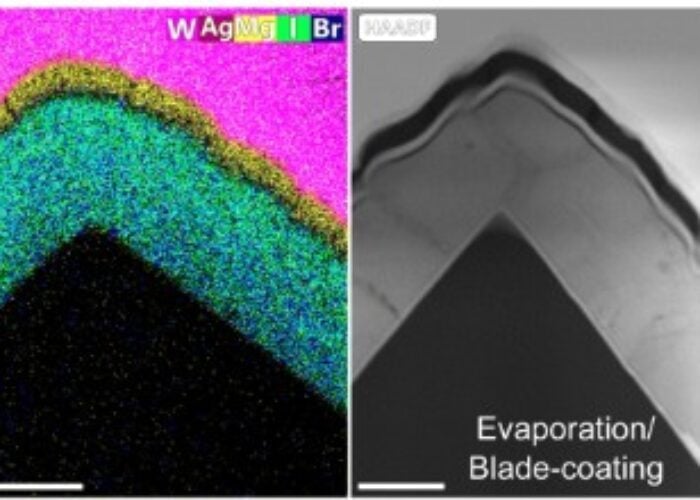

As the perovskite layer of the tandem cells is temperature-sensitive, the Fraunhofer ISE research team developed low-temperature processes for the interconnection and encapsulation of the solar cells that are also particularly gentle on the cells mechanically.

“These are suitable for industrial mass production and can be implemented on commercial systems. The necessary adaptations can also easily be implemented in today’s PV production lines,” said Achim Kraft, group leader for Interconnection Technology at Fraunhofer ISE.

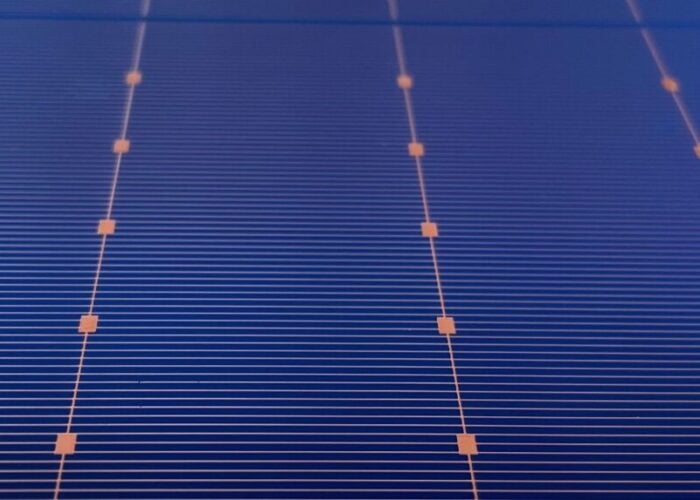

Moreover, the solar cells were interconnected using conductive bonding. Kraft said this type of interconnection was used on an industrial scale at Fraunhofer ISE’s Module-TEC.

“In future, we will also be testing another alternative: soldering the solar cells at low temperatures,” he added.

David Ward, CEO of Oxford PV, said that the record is a milestone.

“(It proves) that our tandem solar cells can deliver record-breaking performance when assembled into solar panels,” he said.

Fraunhofer ISE added that silicon tandem cells have a theoretical maximum efficiency of over 43% compared to less than 30% for silicon solar cells.

For the calibration measurements, the photovoltaic calibration laboratory at the Fraunhofer ISE (CalLab) PV modules used a new multispectral solar simulator to determine the module efficiency. To make precise and reproducible statements about the tandem module’s power, both the perovskite and the silicon cell layers must be illuminated by different LED light sources under conditions that are as close as possible to those in which they produce electricity under natural sunlight.

Currently, both Fraunhofer ISE and Oxford PV are now working on the certification of the PV module.

Last year, Oxford PV also claimed a new world record for commercial solar cell efficiency, recording a 28.6% efficiency on a 258.15 cm2 perovskite tandem cell independently certified by Fraunhofer ISE.

The cell was produced at Oxford PV’s integrated production line in Brandenburg an der Havel, Germany. The organisation stated that “the combined ‘perovskite-on-silicon’ tandem solar cell achieves a conversion efficiency that is substantially higher than that of mainstream silicon-only solar cells, which average 22–24%”.